Active Harmonic Filters: Complete Industrial Power Quality Guide 2025

Industrial and commercial electrical systems face unprecedented power quality challenges from nonlinear devices including LED lighting, variable frequency drives (VFDs), UPS systems, and SMPS units. While these devices improve efficiency, they generate harmonic currents that distort voltage, reduce system efficiency, and damage sensitive equipment.

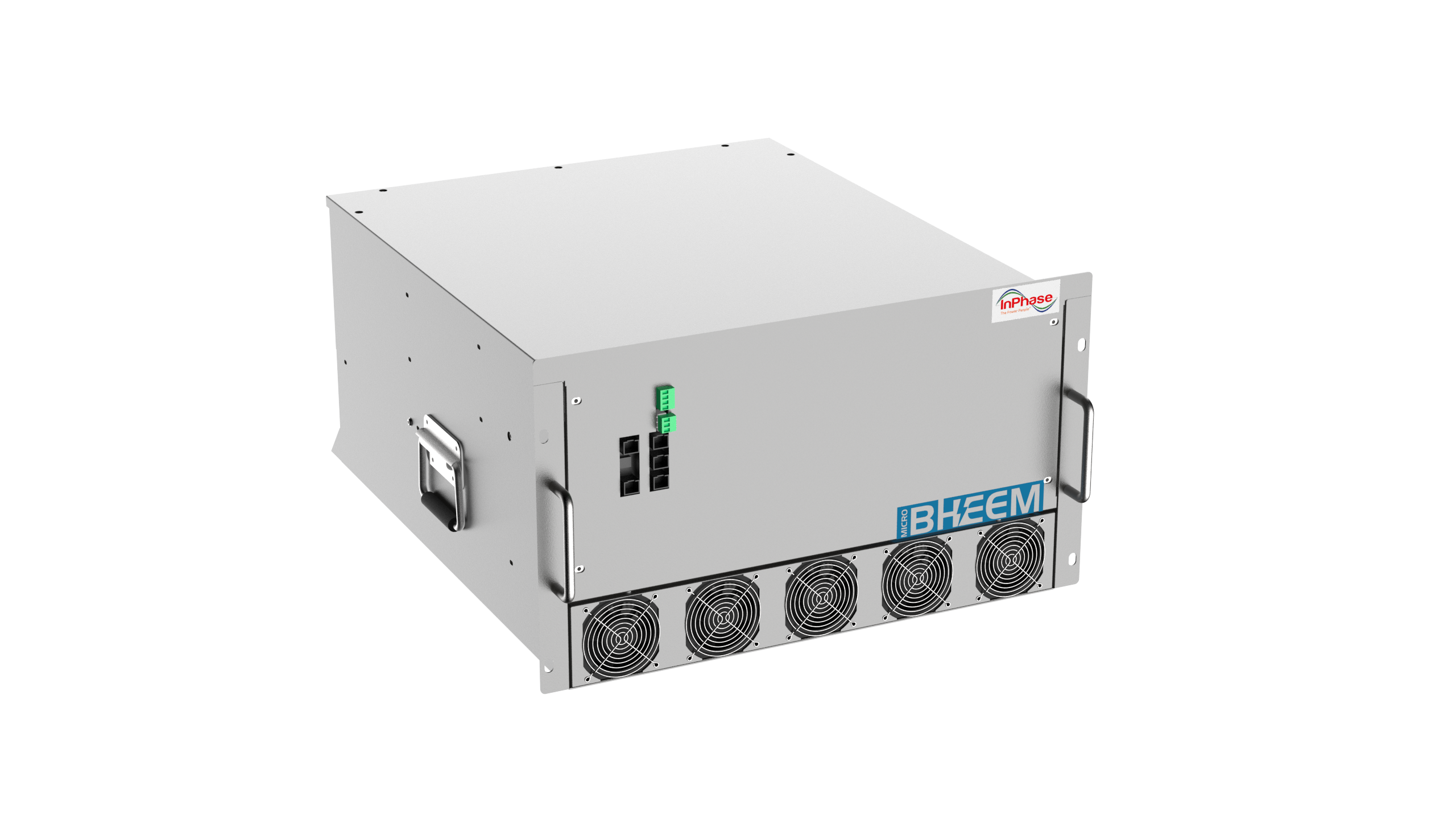

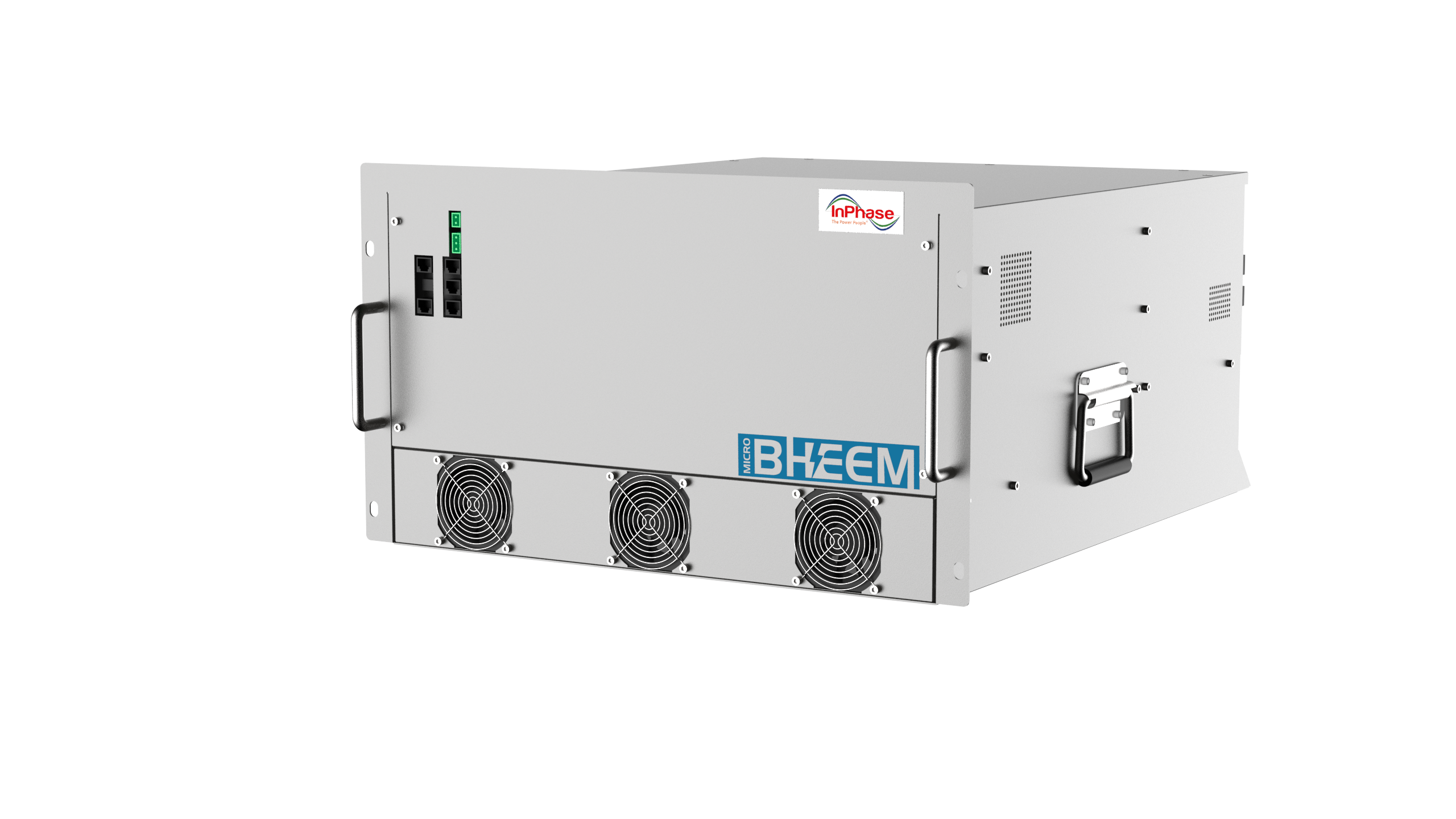

InPhase Active Harmonic Filters (AHFs) provide real-time harmonic detection and cancellation, delivering superior power quality and enhanced system reliability for industrial applications.

Understanding Harmonics in Industrial Power Systems

What Are Power System Harmonics?

Harmonics represent distorted currents and voltages generated by nonlinear loads. Even with perfectly sinusoidal applied voltage, nonlinear devices draw non-sinusoidal currents, creating significant operational problems:

- Transformer and motor overheating leading to premature failure

- Increased cable losses reducing overall system efficiency

- Electronic equipment malfunctioning causing process disruptions

- Capacitor bank failures resulting in costly replacements

Common Sources of Industrial Harmonics

Modern industrial facilities contain numerous harmonic-generating equipment:

- Variable frequency drives controlling motors and pumps

- LED lighting systems and electronic ballasts

- Uninterruptible power supplies (UPS) protecting critical loads

- Switch-mode power supplies in control systems

Why Industrial Facilities Need Active Harmonic Filters

Regulatory Compliance Requirements

IEEE 519 Standards Compliance: Meet strict harmonic limits at the Point of Common Coupling (PCC)

CEA Regulations: Ensure compliance with Central Electricity Authority guidelines for power quality

Utility Penalty Avoidance: Prevent financial penalties for exceeding harmonic distortion limits

Operational Benefits

Energy Efficiency Optimization: Reduce losses in transformers, motors, and distribution cables

Equipment Protection: Extend lifespan of electrical components and prevent premature failures

True Power Factor Improvement: Maintain optimal power factor accounting for both displacement and distortion

Process Reliability: Ensure consistent operation of sensitive automation equipment

InPhase Active Harmonic Filter Technology

Advanced Operation Principle

InPhase AHFs utilize parallel (shunt) connection to the power system for optimal harmonic mitigation:

-

Real-time Monitoring: Current Transformers (CTs) continuously monitor nonlinear load currents

-

Intelligent Analysis: Advanced DSP processing identifies harmonic content and calculates compensation requirements

-

Active Compensation: Filter injects compensating currents 180° out of phase, effectively cancelling harmonics

-

THDi Reduction: Total Harmonic Distortion of current reduced to acceptable levels per IEEE 519 standards

Key Performance Advantages

Comprehensive Harmonic Mitigation

- Reduces THDi below regulatory limits (typically <5%)

- Prevents voltage distortions affecting sensitive equipmentEliminates

- equipment overheating and premature failure

Enhanced Power Factor Correction

- Improves true power factor considering both displacement and distortion

- Reduces reactive power demand (kVAR) and associated costs

- Prevents utility power factor penalties

Superior Equipment Protection

- Extends transformer, motor, and cable operational life

- Prevents capacitor and electronic component failures

- Reduces maintenance costs and unplanned downtime

Improved Energy Efficiency

- Minimizes losses in distribution transformers and cables

- Lowers overall electricity consumption and costs

- Optimizes system performance under varying load conditions

Regulatory Standards Compliance

- Ensures adherence to IEEE 519 harmonic limits

- Meets CEA power quality requirements

- Avoids utility penalties and operational restrictions

Industry-Specific Applications and Results

Food Processing Industry

Challenge: High THDi levels causing frequent electronic component failures

Solution: 200A AHF installation at Point of Common Coupling

Results: THDi reduced to <8%, eliminating equipment failures and improving process reliability

IT/ITES Facilities

Challenge: THDi ~24% with poor power factor from extensive electronic loads

Solution: 75A AHF system targeting harmonic-generating equipment

Results: THDi reduced to <5% with significant power factor improvement

Textile Manufacturing

Challenge: THDi ~12% causing capacitor bank failures and motor overheating

Solution: 600A AHF system for comprehensive facility protection

Results: THDi reduced to <3%, eliminating capacitor failures and extending equipment life

Implementation Best Practices

System Assessment and Sizing

Conduct comprehensive harmonic analysis to determine optimal AHF sizing and placement. Consider load characteristics, growth projections, and regulatory requirements for long-term effectiveness.

Installation Considerations

Install AHFs at strategic locations such as main distribution panels or near major harmonic sources for maximum effectiveness. Ensure proper grounding and protection coordination with existing systems.

Monitoring and Maintenance

Implement continuous monitoring to verify ongoing performance and compliance with harmonic standards. Regular maintenance ensures optimal operation and extends system lifespan.

Return on Investment Analysis

Direct Cost Savings

- Reduced utility penalty charges for power factor and harmonic violations

- Lower energy consumption through improved system efficiency

- Decreased equipment replacement costs due to extended lifespan

Operational Benefits

- Improved process reliability reducing production losses

- Enhanced equipment performance and reduced maintenance requirements

- Compliance with utility interconnection standards

Industrial facilities implementing InPhase Active Harmonic Filters achieve comprehensive power quality improvement through effective harmonic mitigation, enhanced power factor correction, extended equipment protection, improved energy efficiency, and regulatory compliance assurance.

Ready to optimize your industrial power quality? Contact InPhase Power Solutions today for professional Active Harmonic Filter assessment and implementation services designed to maximize your facility’s electrical system performance and reliability.

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

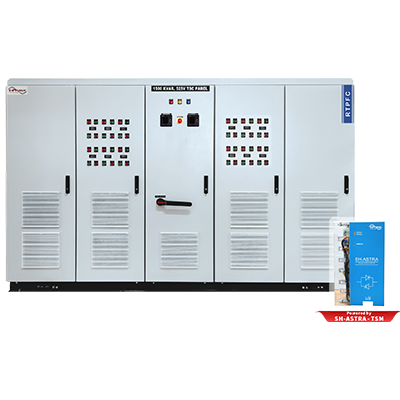

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support