| Solutions | 50A, 75A, 100A, 150A, 200A |

| Voltage | 350V-480V |

| Types | 3Phase 4Wire |

| Harmonics | Up to 50th Order |

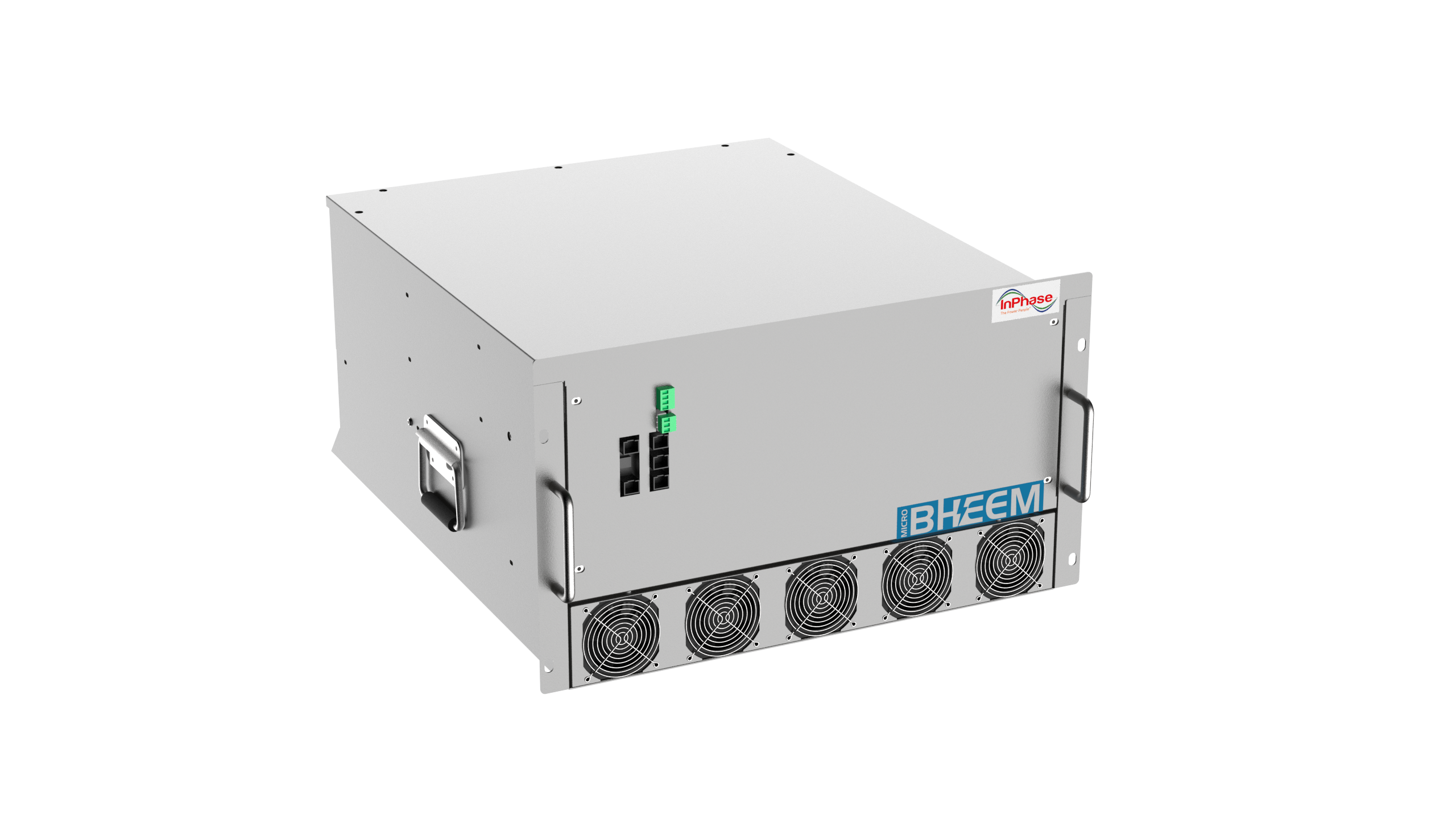

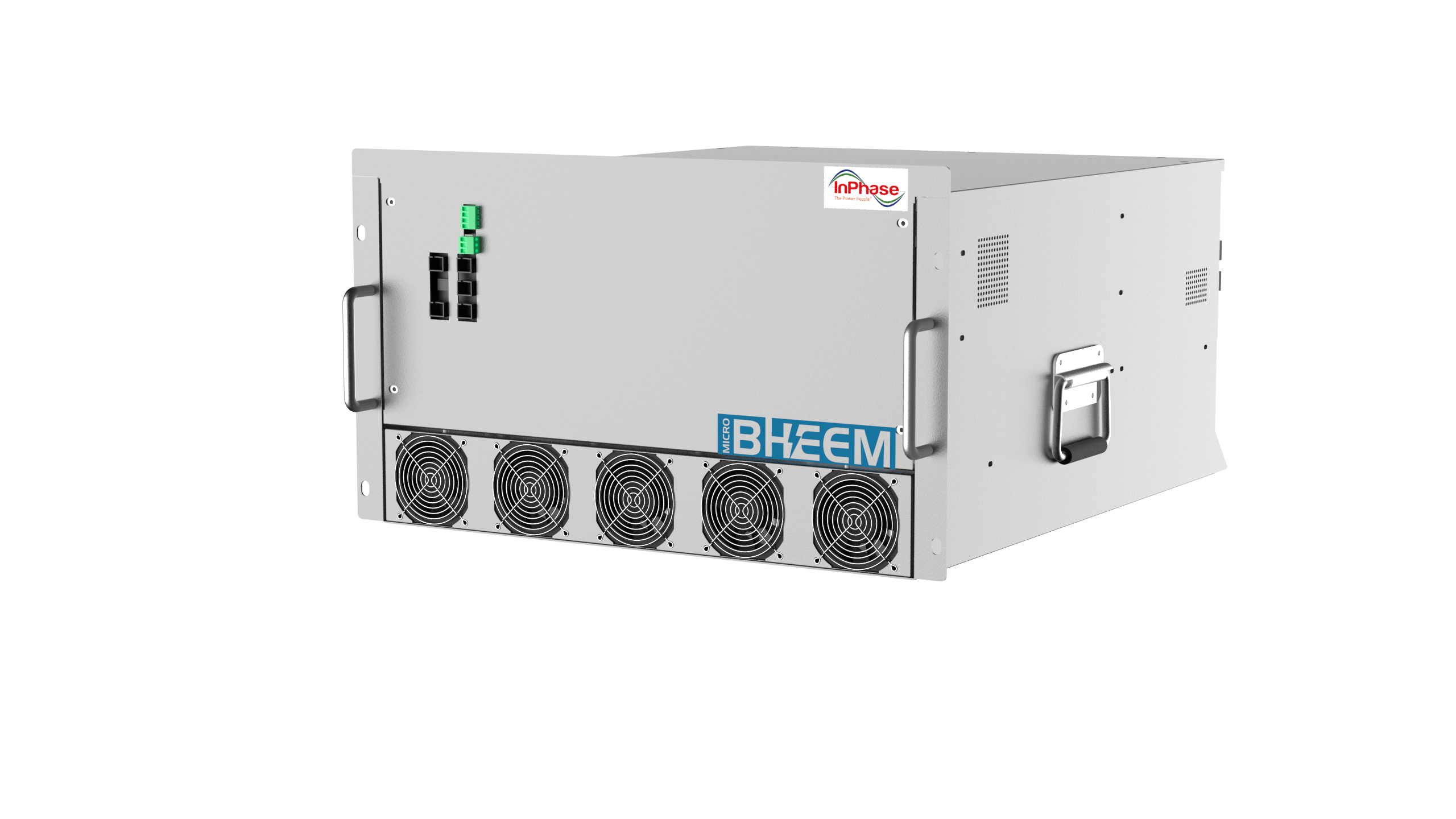

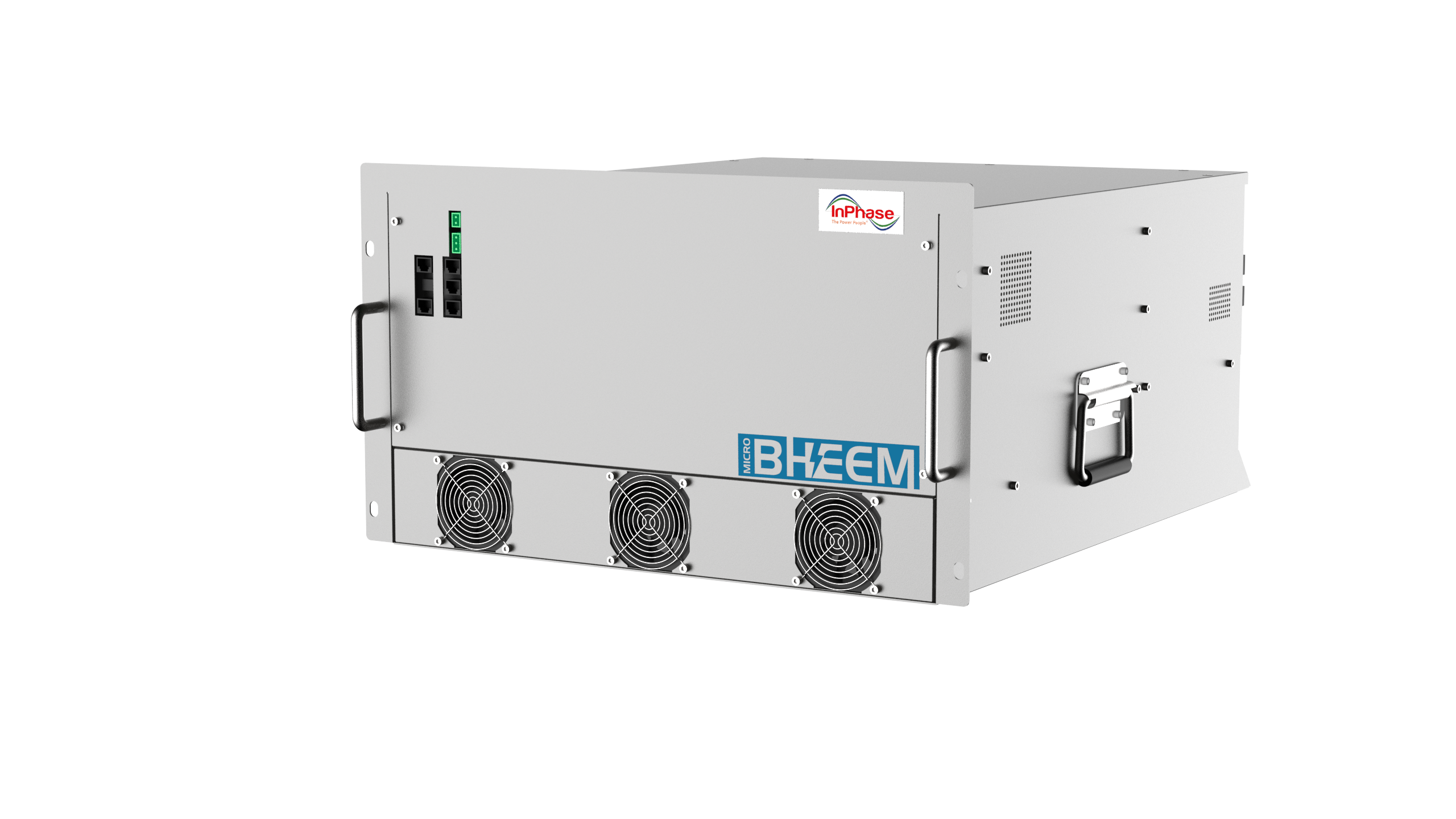

Modular AHF

Modular Compensation System

- 3-Level IGBT

- Extremely Efficient – 98%

- Comprehensive Harmonic Management

- Flexible Operation Mode

- Smart Integration

- Real-time adaptive filtering technology

- Robust construction for harsh environments

Steel, Cement, Textile, Data Centers, Paper Mils, Chemical Plants, Railways, Process, Automotive and other manufacturing Industries

Modular Active Harmonic Filter (AHF) is an advanced, electronics-based system designed to eliminate harmful harmonics from electrical networks. Unlike passive filters, Modular AHF dynamically detects and cancels harmonic currents in real time, improving power quality and protecting sensitive equipment.

Built on InPhase’s , Modular AHF supports expansion up to 32 units, offers real-time harmonic mitigation up to the 50th order, and includes reactive power compensation and load balancing. Whether the load requires 30A, 100A, or 210A, the Modular AHF adapts instantly, ensuring consistent and efficient performance.

It is ideal for industries like steel, automotive, textiles, data centers, and more where non-linear loads generate harmonics and cause equipment inefficiencies or failures.

For Module ( AHF & SVG ) related inquiries contact

Further reading on Power Quality.....

FAQ

Harmonics are electrical distortions that occur when the current or voltage waveform deviates from the

perfect sine wave. Think of it as “electrical noise” in your power system.

Simple explanation: Your electrical system should run on a smooth 50Hz sine wave, but non-linear

equipment like computers, drives, and LED lights create additional frequencies (multiples of 50Hz like

150Hz, 250Hz, 350Hz, etc.). These additional frequencies are called harmonics.

Problems caused by harmonics:

- Equipment overheating and premature failure

- Increased electricity bills

- Nuisance tripping of breakers

- Motor vibrations and noise

- Transformer and cable heating

- Interference with sensitive electronics

Reactive Power is the power that electric equipment needs to create magnetic fields (like in motors,

transformers) but doesn’t actually do useful work.

Simple explanation:

- Active Power = Does actual work (lighting, heating, motor rotation)

- Reactive Power = Creates magnetic fields needed for equipment to operate but doesn’t do work.

- Power Factor = Ratio of useful power to total power drawn.

Why it’s important:

- Poor power factor means you pay for power you can’t use

- Utilities penalize low power factor (typically below 0.9 or 0.95)

- Causes higher current draw, leading to cable losses and equipment stress

- Reduces system capacity and efficiency.

Example: If your power factor is 0.8, you’re paying for 25% more power than you actually need for useful

work.

SVG: Primarily corrects power factor by providing reactive power (leading or lagging). Think of it as

an advanced, fast-responding replacement for capacitor banks

Harmonic Filter: Removes electrical noise (harmonics) caused by non-linear loads like drives, UPS,

computers, and LED lights

Key difference: SVG fixes power factor issues, Harmonic Filter cleans up electrical noise

APFC (Traditional Method):

- Uses fixed capacitors and reactors

- Stepwise correction (cannot provide exact compensation)

- Slower response time

- Limited to power factor correction only

- Lower cost but less precise

Active Compensation (Modern Method):

- Uses power electronics (IGBT technology)

- Provides exact, real-time compensation

- Instantaneous response (within 1 power cycle)

- Can handle both power factor AND harmonics

- Higher initial cost but superior performance and flexibility

It depends on your electrical system:

- Only Power Factor issues: Choose SVG

- Only Harmonic issues: Choose AHF+

- Both issues: Choose SVG+ or AHF (which can handle both simultaneously)

- Severe harmonic problems: Choose AHF or AHF+ for comprehensive filtering

Signs of harmonic issues:

- Frequent bulb/LED failures

- Cable and transformer heating

- Nuisance tripping of circuit breakers

- Motor breakdowns and drive failures

- High electricity bills despite good power factor

- Equipment malfunctions or reduced lifespan

Common harmonic sources:

- Variable Frequency Drives (VFDs)

- UPS systems

- Computers and servers

- LED lighting

- SMPS (Switch Mode Power Supplies)

- Welding equipment

- Any equipment with rectifiers or inverters

- Choose SVG if you only need power factor correction and load balancing

- Choose SVG+ if you need power factor correction plus basic harmonic filtering (up to 13th order)

- Choose AHF if you need comprehensive power quality management with flexible operation modes

- Choose AHF+ if advanced harmonic filtering (up to 50th order) is your primary requirement

SVG/SVG+: Primarily designed for reactive power compensation (power factor improvement) with

optional basic harmonic filtering AHF/AHF+: Designed for comprehensive harmonic filtering with

optional power factor correction capabilities

- SVG & SVG+: 25kVAR to 150kVAR

- AHF & AHF+: 30A to 210A

- SVG: No harmonic filtering

- SVG+: Up to 13th order harmonics (4 selectable frequencies)

- AHF: Up to 25th order harmonics (10 selectable frequencies)

- AHF+: Up to 50th order harmonics (20 selectable frequencies)

Yes, you can connect up to 32 units in parallel for any combination of capacities to meet your exact

requirements.

- SVG: Power factor correction (100%) + Current balancing (30%)

- SVG+: Power factor mode OR Hybrid mode (30% harmonics + 70% power factor)

- AHF: Pure harmonic mode OR Pure power factor mode OR Hybrid mode (50-50 split)

- AHF+: Dedicated harmonic filtering only (100%)

- Indoor installation only

- Adequate ventilation is essential (air conditioning recommended)

- Dust-free environment preferred

- Operating temperature: 0°C to 40°C

- Regular cleaning with air pressure to prevent heat sink clogging

Minimal maintenance needed:

- Regular cleaning of heat sinks and fans using air pressure

- Ensure proper ventilation to prevent overheating

- Keep installation area dust-free

We guarantee 10-year parts availability and provide long-term product support. The products use high

quality film capacitors for extended lifespan.

- ASTRA: Custom-built solutions for specific power quality problems with extensive customization

- MicroBheem: Standard modular products sold as plug-and-play modules for integration into

electrical panels

Yes, we offer:

- Real-time technical support

- Employee training programs

- Solution design support

- Long-term after-sales service

Yes, SVG and SVG+ models support hybrid operation and can integrate seamlessly with existing APFC

(Automatic Power Factor Controller) panels, making your passive system more efficient.

- Local support: Better accessibility and faster response times

- Proven reliability: 10+ years of industrial experience with ASTRA technology

- Long-term commitment: Guaranteed parts availability and consistent service

- Indian conditions: Designed specifically for harsh Indian industrial environments

- No import risks: No customs delays or currency fluctuation issues

Manufacturing: Automotive, textiles, steel, cement, paper mills

Infrastructure: Data centers, hospitals,

commercial buildings, metro stations

Process Industries: Chemical plants, pharmaceutical facilities, water treatment

You need harmonic filtering if you have:

- Variable Frequency Drives (VFDs)

- UPS systems

- LED lighting

- SMPS equipment

- Computers and servers

- Any non-linear loads causing equipment failures, cable heating, or transformer issues

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support