Introduction

Industries today are more power-hungry and complex than ever. With rising automation, drives, and electronic loads, power systems face increasing stress from reactive power demand and harmonics. This directly impacts efficiency, increases losses, and may attract penalties from utilities.

Traditional reactive power compensation methods like capacitor banks and SVCs often fall short in today’s dynamic environment.

This is where the Static VAR Generator (SVG) steps in—a modern solution providing real-time, precise, and dynamic reactive power compensation.

What is a Static VAR Generator?

An SVG is a power electronic-based device that injects or absorbs reactive power into the grid to maintain desired power factor, voltage stability, and harmonic performance. Fully digital and sub-cycle responsive, SVGs are ideal for modern industries.

Think of an SVG as the “guardian of grid quality”—silently monitoring, adjusting, and ensuring your electrical system runs at its best.

Why Reactive Power Compensation Matters

Reactive power doesn’t perform useful work, but it is essential for motors and transformers. Excessive reactive demand can lead to:

- Poor power factor and higher utility bills

- Voltage instability

- Overloading of transformers and cables

- Grid code violations and penalties

- Reduced equipment lifespan

Industries like steel, cement, textiles, IT parks, hospitals, and data centers experience direct operational and financial impacts from reactive power mismanagement.

Conventional Solutions: Their Limitations

- Capacitor banks or APFC panels: inexpensive but slow and prone to resonance issues

- Static VAR Compensators (SVCs): better but slower due to thyristor-controlled elements

Both fail under rapidly fluctuating loads as seen in arc furnaces, rolling mills, robotics, or VFD-driven systems.

Why SVG is the Game-Changer

SVGs overcome these limitations with:

- Dynamic response (<10 ms): instantly compensates reactive power changes

- Bidirectional support: injects or absorbs VARs as needed

- Precise control: maintains power factor near unity at all times

- Harmonic mitigation: reduces distortion from nonlinear loads

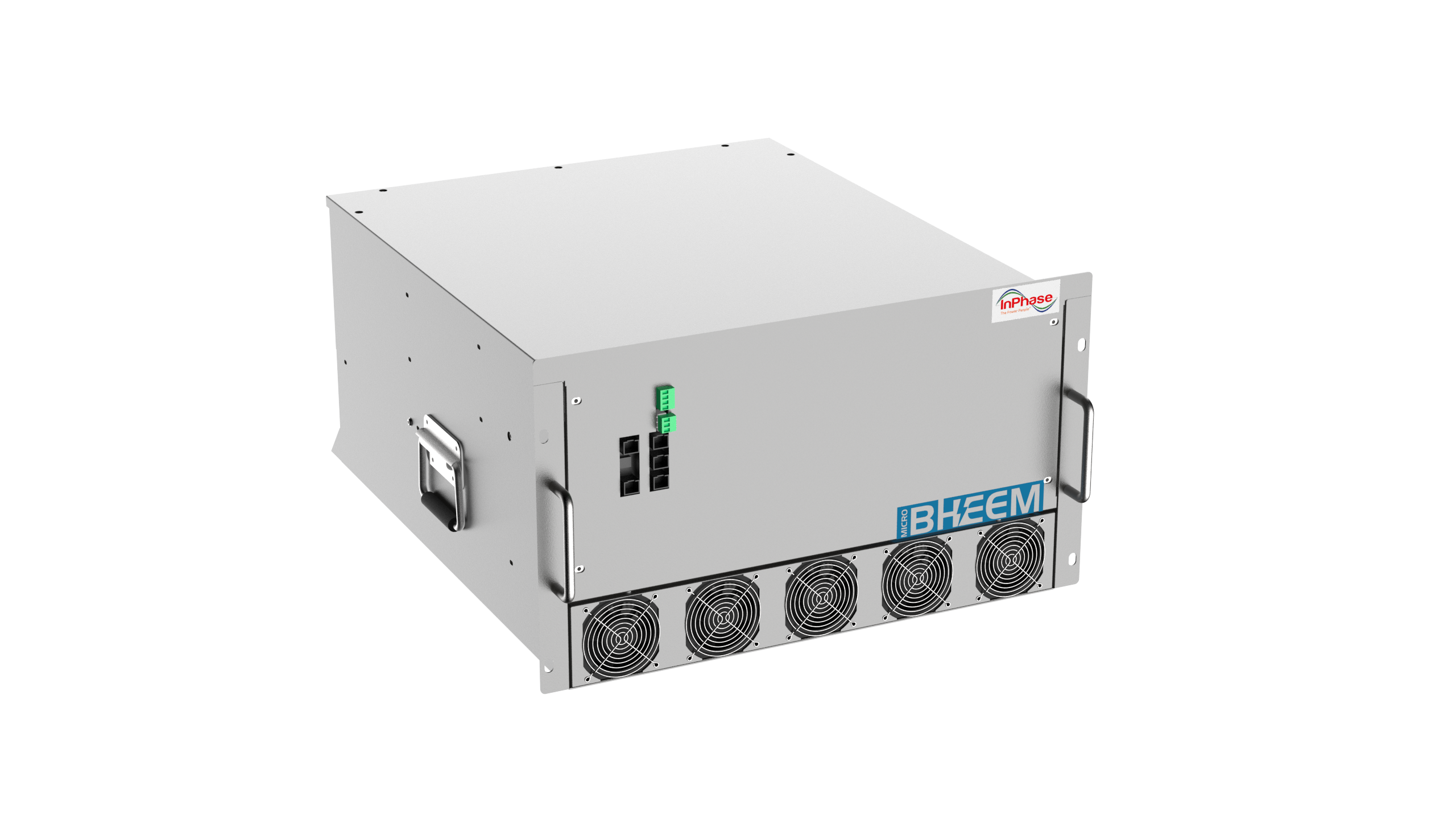

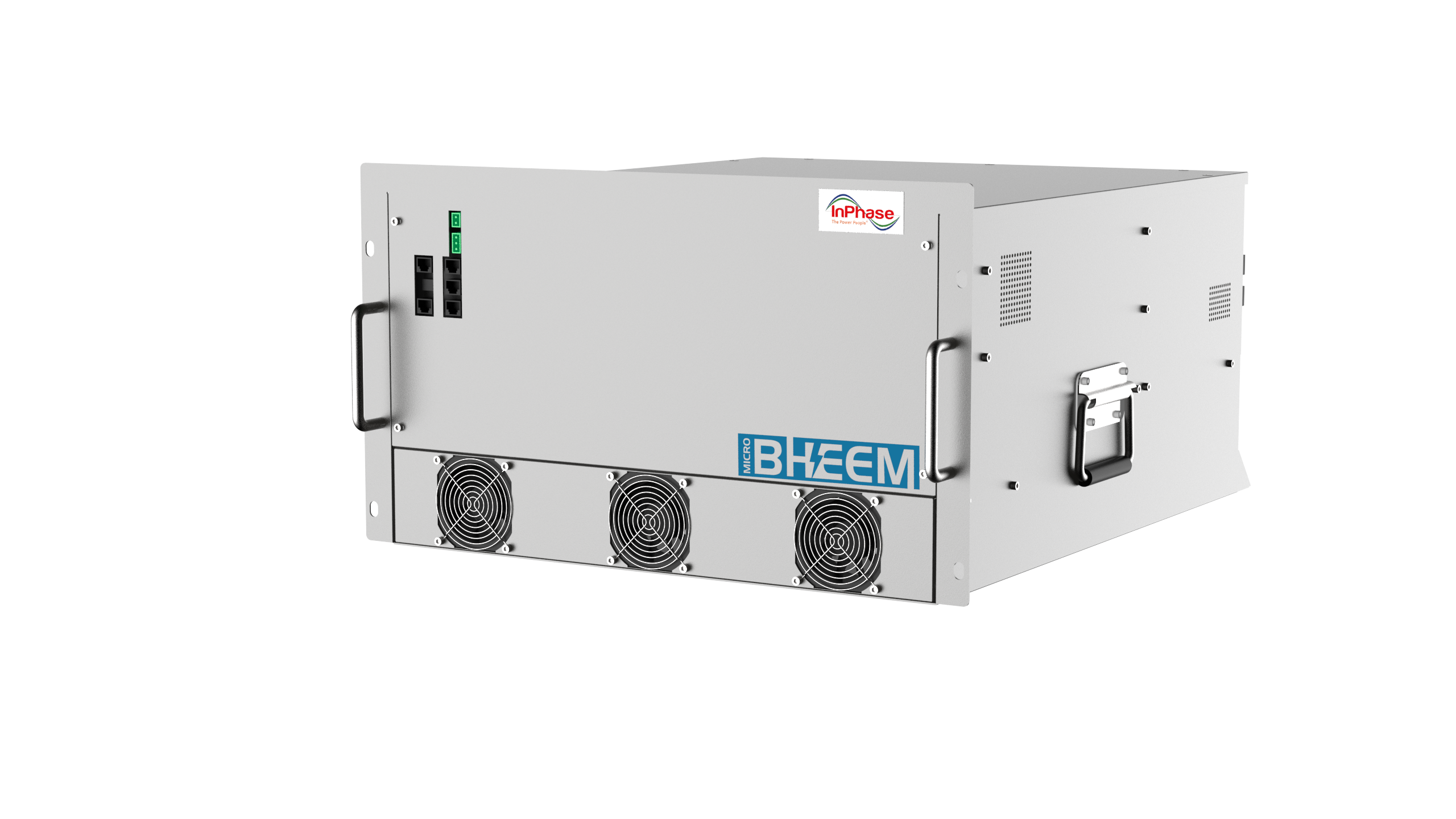

- Compact and modular design: easy to scale and integrate

- 24/7 reliability: built for continuous industrial duty

Applications of SVG

- Steel & Metal Processing Plants: Manage flicker, heavy load fluctuations, and harmonics

- Cement Industry: Stabilize grinding mills, crushers, and rotary kilns

- Hospitals & Data Centers: Ensure uninterrupted power quality for critical systems

- Renewable Integration: Maintain grid stability in solar and wind farms

- IT Parks & Commercial Buildings: Improve efficiency and reduce electricity costs

SVG vs. Conventional Solutions

| Feature | Capacitor Banks | SVC | SVG |

| Response Time | Seconds | 100–200 ms | <10 ms |

| Harmonic Mitigation | No | Limited | Yes |

| Scalability | Low | Medium | High |

| Reliability | Moderate | Good | Excellent |

| Cost Efficiency | Low upfront | Medium | High ROI over life cycle |

Benefits for Businesses

- Reduced energy bills through improved power factor

- Avoid utility penalties

- Extend equipment life by reducing stress

- Stable operations with minimal downtime

- Contribute to sustainability by reducing energy wastage

Conclusion

As industries evolve, power management must evolve too. SVGs are essential for sustainable, reliable, and cost-efficient operations.

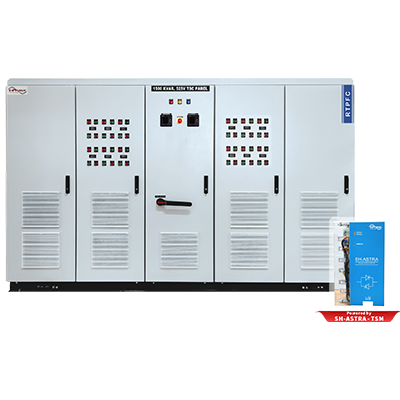

InPhase SVG solutions combine cutting-edge technology with proven reliability, offering more than equipment—they provide efficiency, compliance, and future readiness.

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support