SHAF Technology: Revolutionizing Industrial Power Management with Smart Hybrid Active Filters

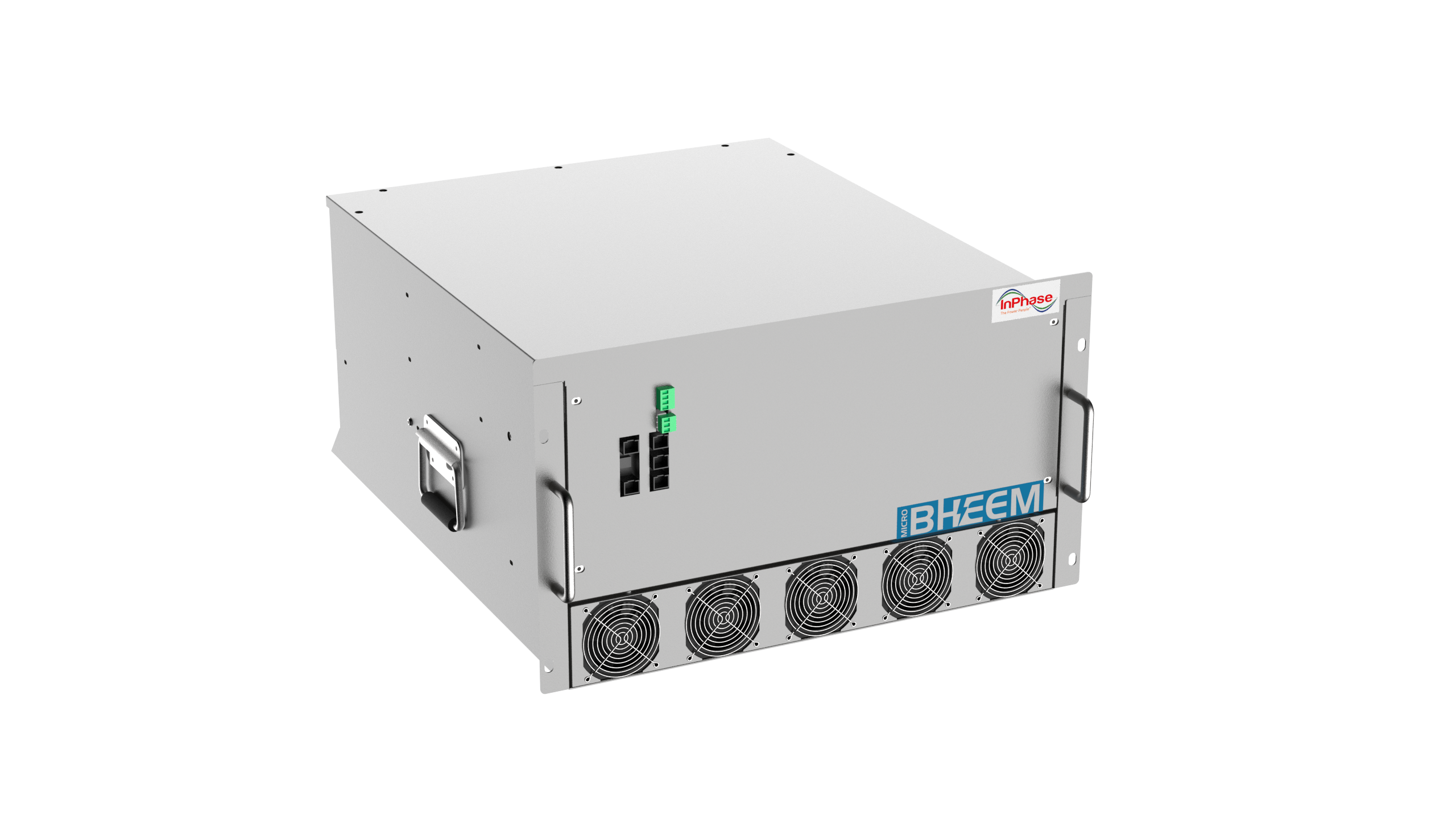

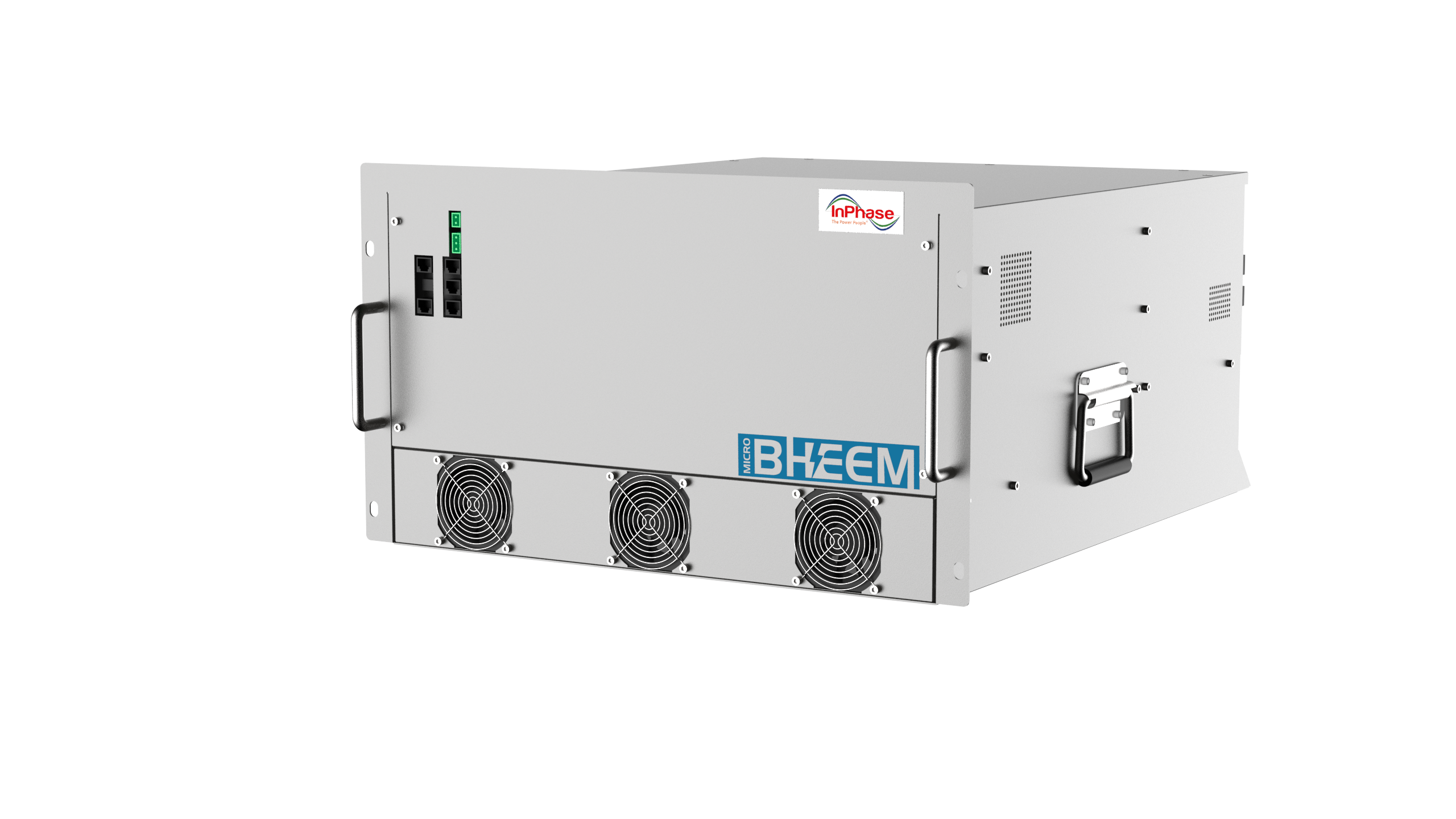

Industrial facilities across India are facing unprecedented challenges with rising electricity costs and stringent KVAH billing regulations. The introduction of Smart Hybrid Active Filter (SHAF) technology by InPhase represents a groundbreaking solution that combines the best of both active and passive power factor correction methods to deliver superior performance at a fraction of traditional costs.

What is SHAF Technology?

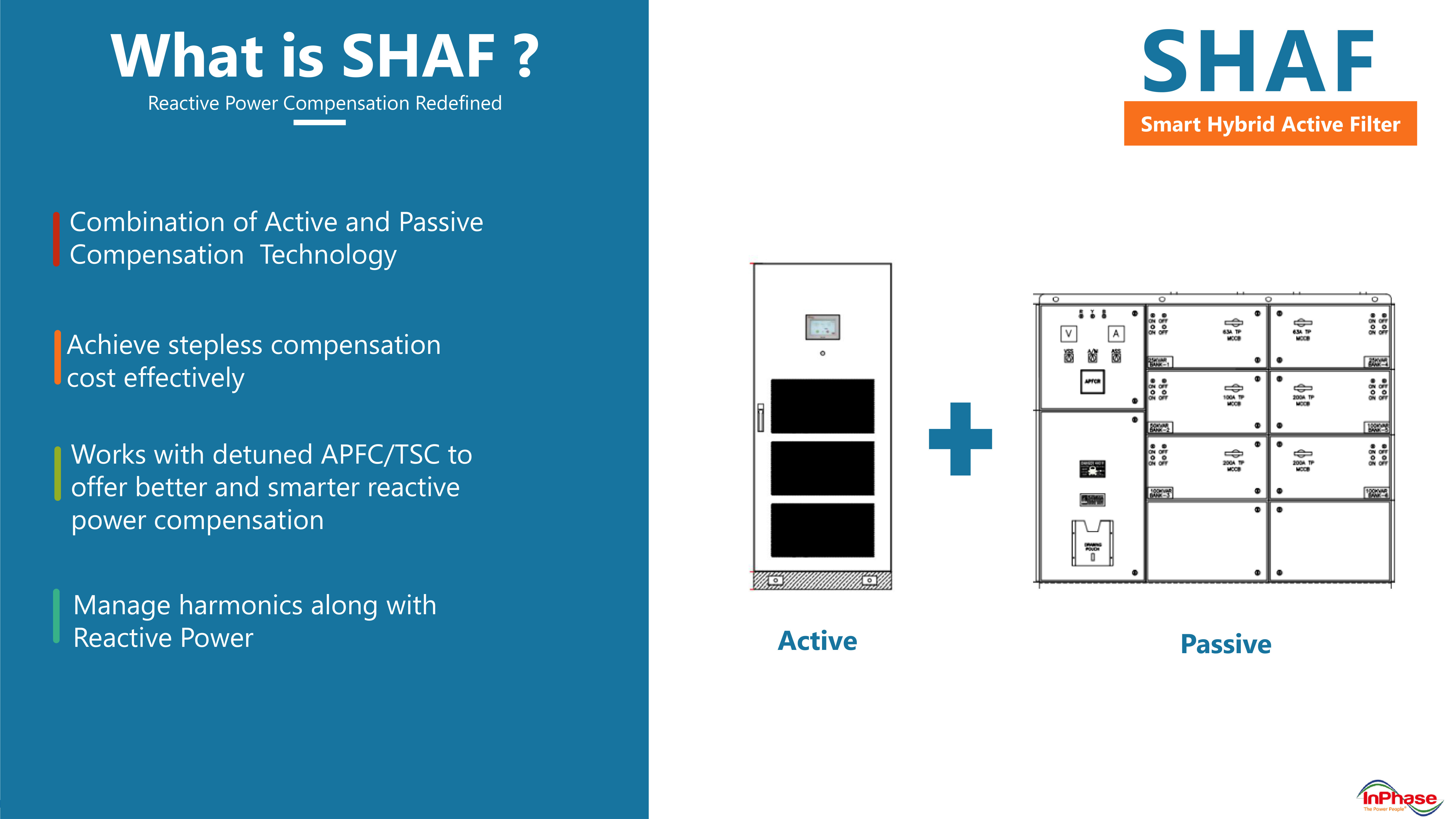

SHAF (Smart Hybrid Active Filter) represents a paradigm shift in reactive power compensation technology. Unlike conventional APFC (Automatic Power Factor Correction) systems that rely solely on passive components, SHAF integrates both active and passive compensation technologies to achieve stepless, dynamic power factor correction. This hybrid approach enables industries to maintain unity power factor while simultaneously managing harmonics, resulting in significant cost savings and improved system efficiency.

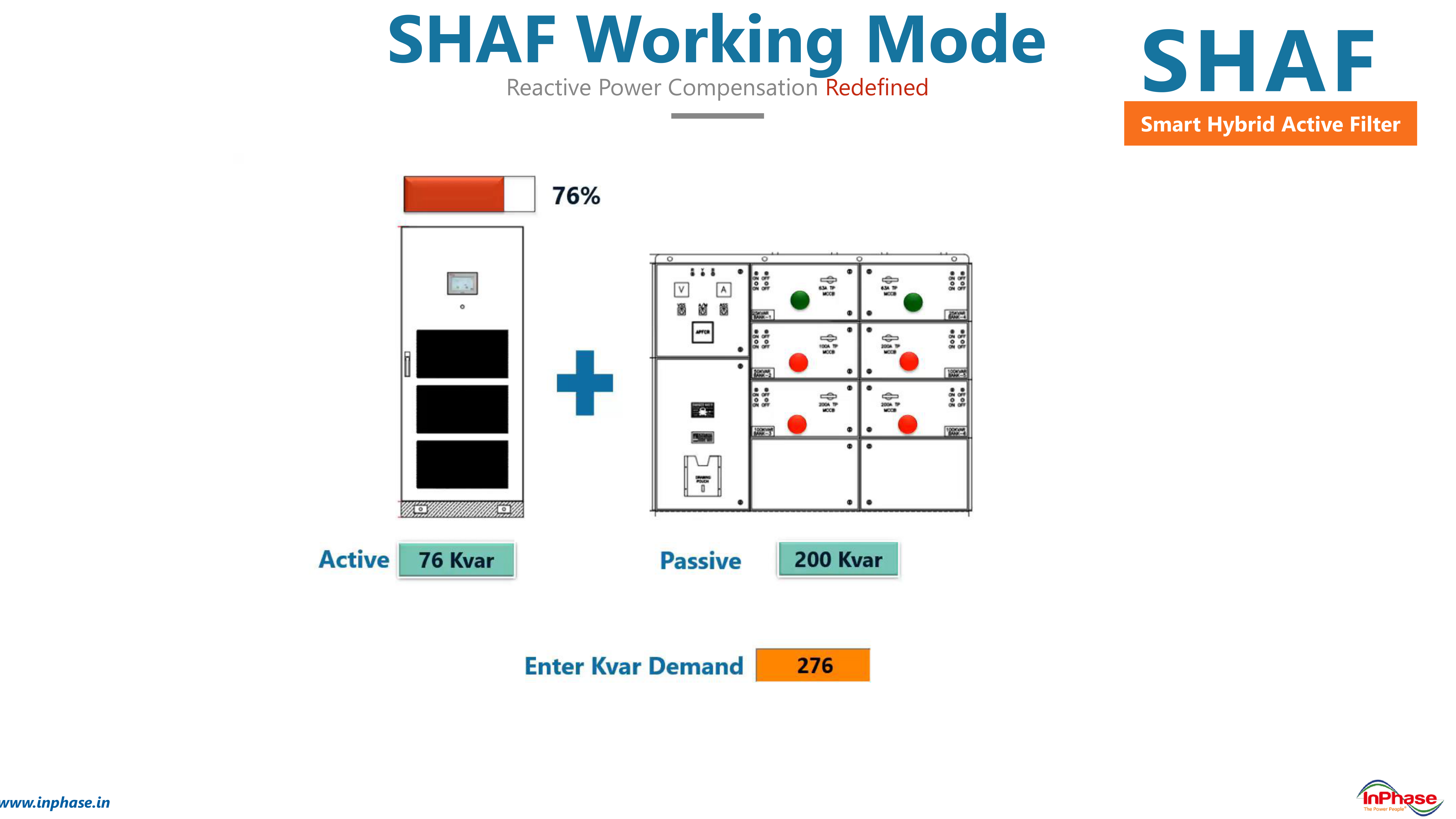

The technology works by utilizing passive components (capacitors) for bulk reactive power compensation while employing active components for fine-tuning and rapid response to dynamic load changes. This intelligent combination ensures precise KVAR delivery without the risk of over-compensation or under-compensation that plagues traditional systems.

Key Components and Architecture

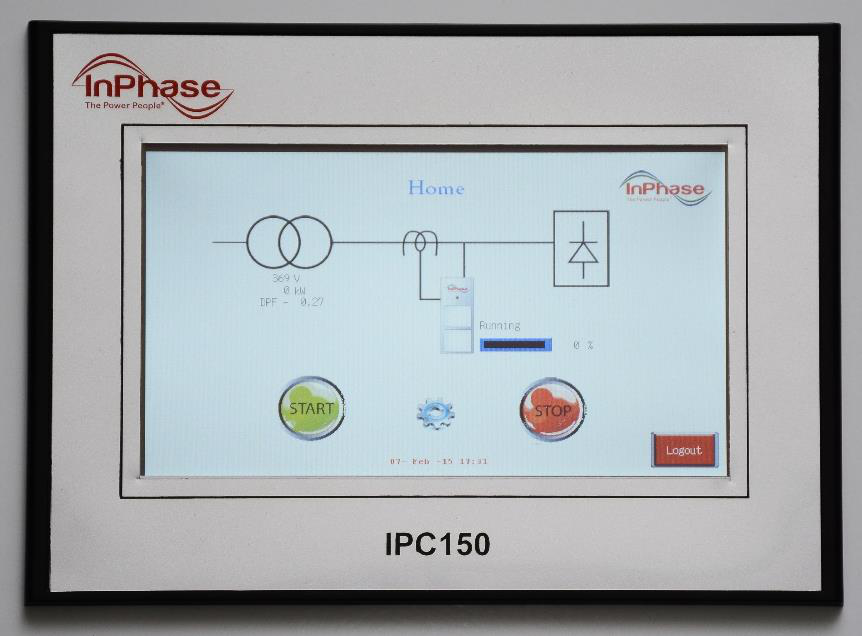

SHAF systems comprise sophisticated high-speed DSP controllers that enable rapid sampling and calculation capabilities far superior to conventional microcontroller-based APFC systems. The system features a 7-inch HMI interface that provides comprehensive system monitoring and control, eliminating the need for small, difficult-to-use traditional displays.

The active component handles fine corrections with response times as fast as 20 milliseconds, while the passive component manages the bulk reactive power requirements. This configuration allows for optimal sizing based on load profiles, with active-to-passive ratios ranging from 10:90 for constant loads to 40:60 for highly dynamic applications.

Revolutionary Benefits of SHAF Technology

Cost-Effective Solution

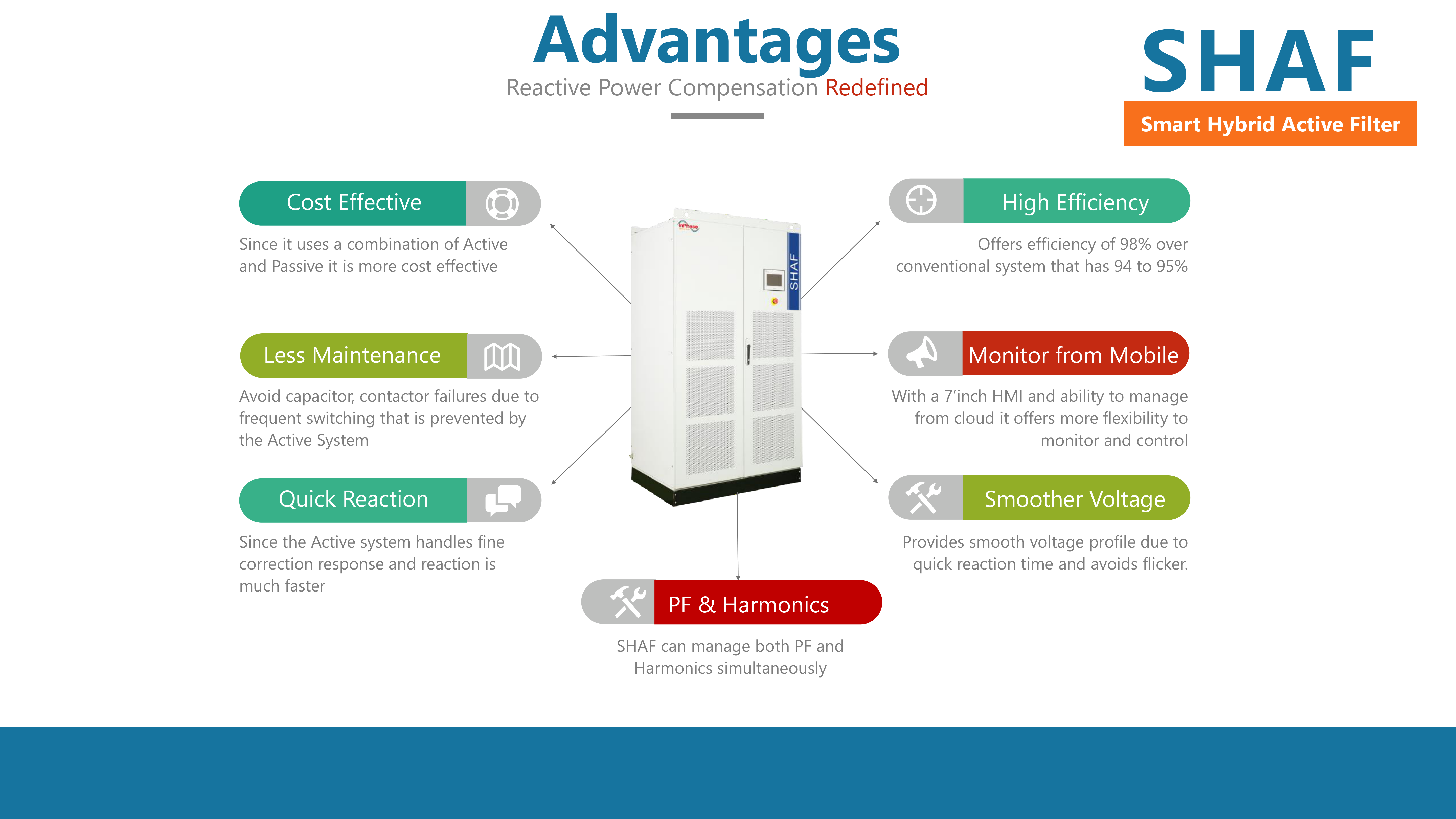

Traditional active filters require 100% active components, making them prohibitively expensive for many industrial applications. SHAF technology dramatically reduces costs by utilizing existing APFC systems where possible, requiring only 10-40% active compensation depending on the load profile. This approach delivers the performance benefits of active filtering at a fraction of the cost.

Industries can achieve significant savings by avoiding power factor penalties that utility companies typically impose on facilities with power factors below 0.80 or 0.85. The precise KVAR delivery capability of SHAF systems ensures consistent unity power factor maintenance, eliminating penalty charges entirely.

Enhanced System Efficiency

SHAF systems deliver remarkable efficiency improvements, achieving 98% efficiency compared to conventional systems that typically operate at 94-95% efficiency. This 3-4% improvement in efficiency translates to substantial energy cost savings over the system’s operational lifetime.

The technology prevents frequent switching of capacitor contactors, which extends equipment lifespan and reduces maintenance requirements. By eliminating small steps in APFC systems that are prone to frequent switching and failure, SHAF ensures more reliable long-term operation.

KVAH Billing Optimization

With the widespread adoption of KVAH billing across Indian states including Maharashtra, Telangana, and Gujarat, industries face increased electricity costs due to reactive power consumption. SHAF technology directly addresses this challenge by maintaining unity power factor and preventing leading compensation, which is crucial for KVAH billing optimization.

The system’s ability to provide both leading and lagging compensation ensures optimal reactive power management regardless of load conditions. This capability is particularly valuable in industrial settings with varying load profiles throughout operational cycles.

Advanced Technical Capabilities

Lightning-Fast Response Time

SHAF systems feature blazing-fast 20-millisecond response times, enabling real-time compensation for rapidly changing load conditions. This instant response capability is achieved through high-speed DSP controllers that sample at extremely high rates and implement intelligent switching algorithms.

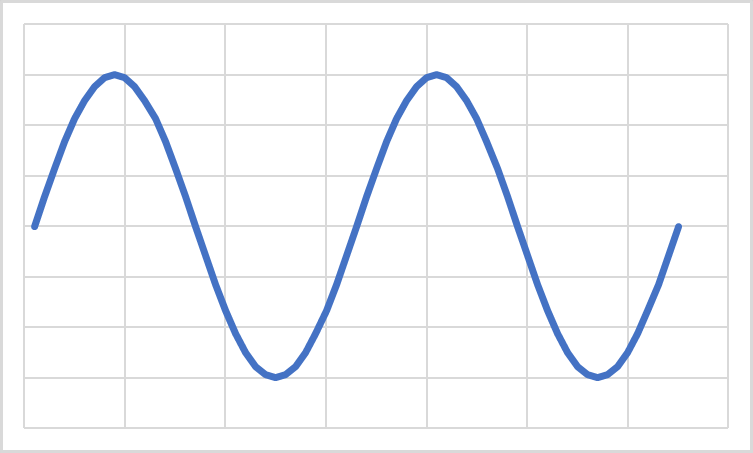

The rapid response time eliminates voltage fluctuations and flicker that commonly occur with conventional stepped compensation systems. This results in smoother voltage profiles and improved power quality throughout the facility.

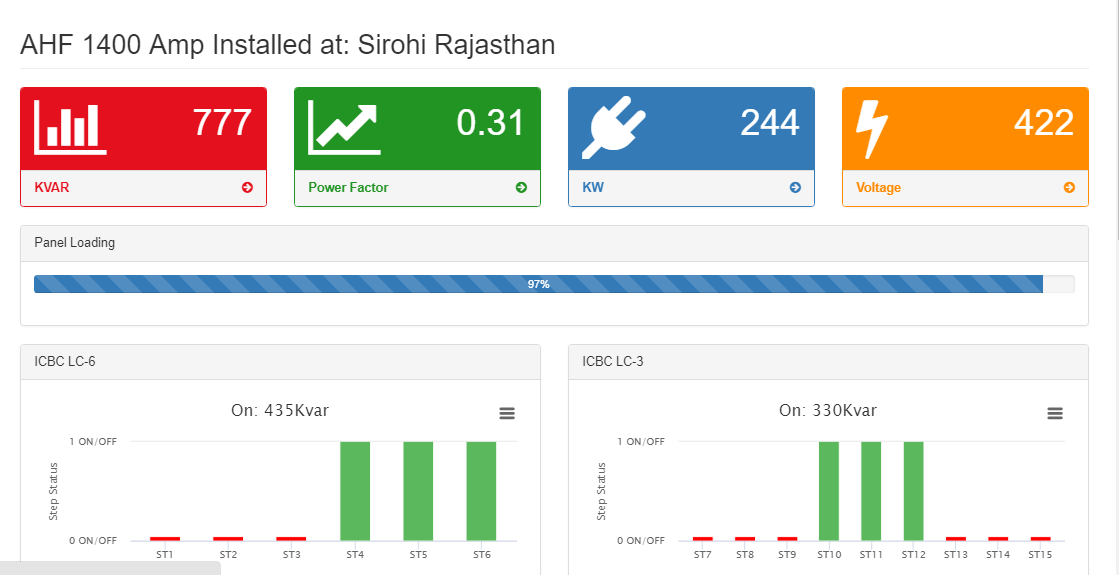

Comprehensive System Monitoring

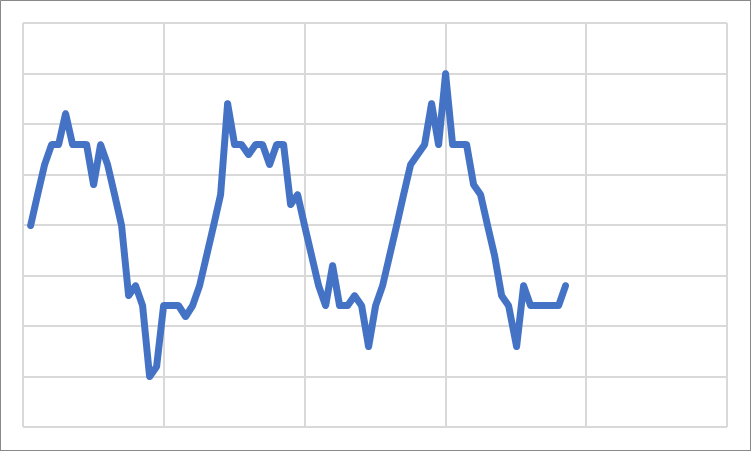

Every SHAF installation includes integrated Energy Management System (EMS) capabilities accessible via mobile devices. The system continuously monitors critical parameters including KWH, KVAR, power factor, and THDi (Total Harmonic Distortion current) with real-time updates every few minutes.

Data storage capabilities extend up to three months by default, with unlimited expansion options available for long-term trending and analysis. Automatic SMS fault notifications ensure immediate awareness of system issues, minimizing downtime and maintenance response times.

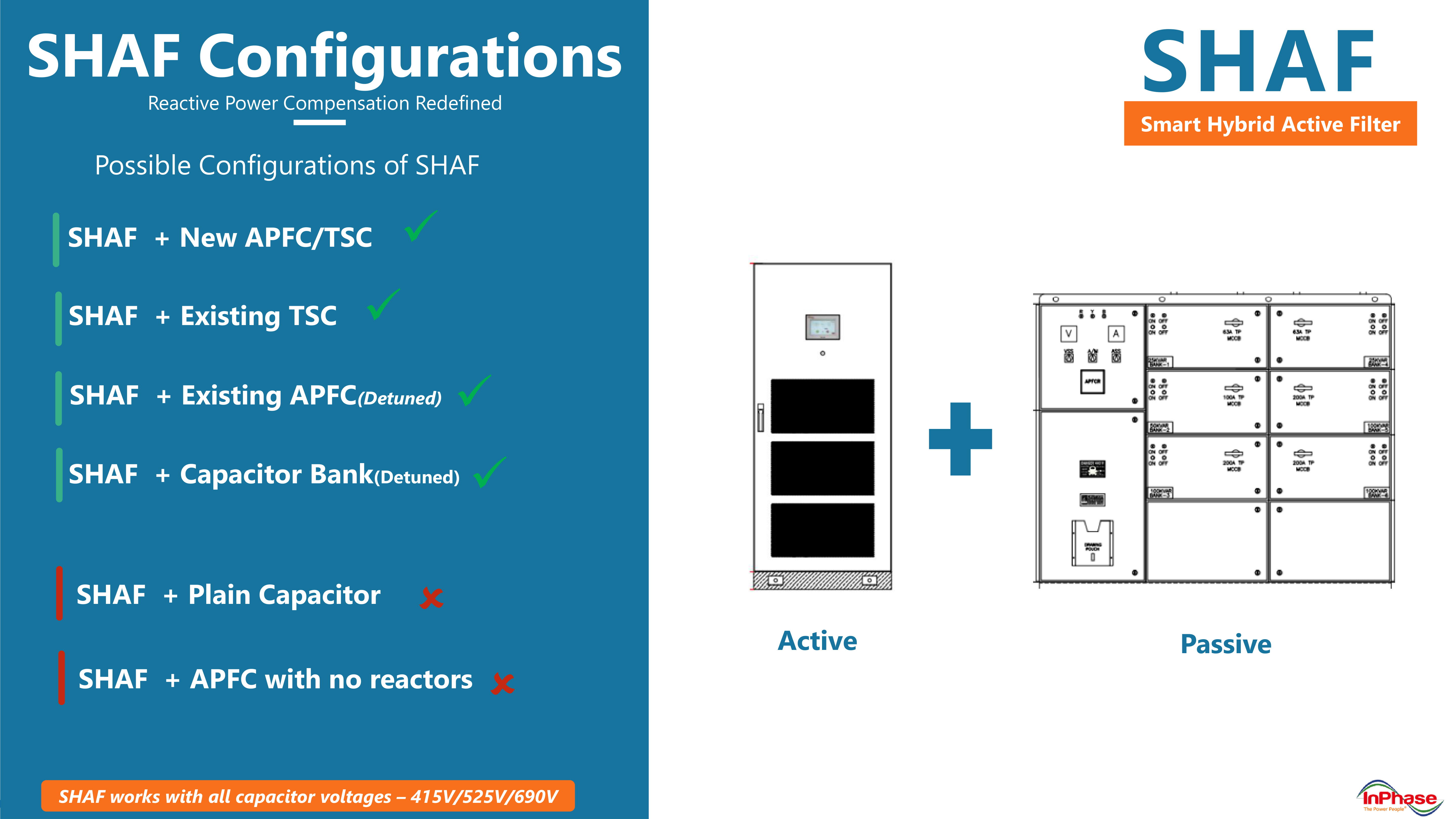

Flexible Configuration Options

SHAF technology demonstrates remarkable versatility by working with various existing power factor correction setups. The system seamlessly integrates with existing TSC (Thyristor Switched Capacitor), detuned APFC systems, capacitor banks, and even plain capacitor installations.

This flexibility enables industries to leverage existing investments while upgrading to advanced hybrid technology. The system operates effectively across all standard capacitor voltages including 415V, 525V, and 690V configurations.

Industrial Applications and Success Stories

Diverse Industry Implementation

SHAF technology has been successfully deployed across over 200 industrial clients spanning multiple sectors. Major implementations include steel manufacturing, cement production, metro rail systems, textile and spinning mills, processing industries, paper manufacturing, automotive, and pharmaceutical facilities.

Notable installations include major PSU companies such as PGCIL, BHEL, NMDC, CMRL, MGL, and Midhani. International deployments extend across India, Canada, Mozambique, Vietnam, and Bahrain, demonstrating the technology’s global applicability.

Real-World Performance Data

Documented installations showcase impressive results across various applications. A 2 MVAR hybrid compensation system successfully demonstrated cost-effective solution implementation, while a 1.5 MVAR installation specifically focused on KVAH billing reduction achieved significant cost savings.

Floating grid power factor compensation applications utilizing 2 MVAR systems have proven effective in challenging grid conditions, while dedicated reactive power compensation installations up to 2.5 MVAR have delivered consistent performance improvements.

Competitive Advantages Over Traditional Solutions

SHAF vs Traditional APFC Systems

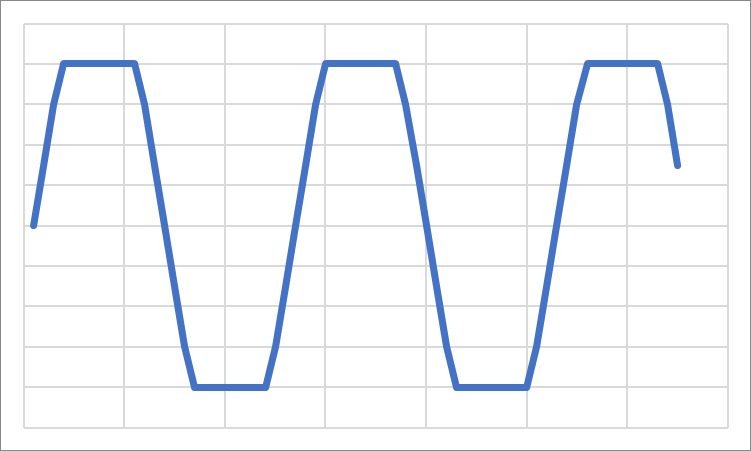

Traditional APFC systems suffer from fundamental limitations including stepped reactive power compensation, frequent capacitor and contactor switching that reduces equipment lifespan, and poor response times. These systems also struggle with over-compensation and under-compensation issues, occupy significant space, and can only manage power factor without harmonic control.

SHAF technology addresses every limitation through dynamic stepless compensation, intelligent capacitor control that minimizes switching, compact design, and simultaneous power factor and harmonic management. The system delivers both lagging and leading compensation with instant response times measured in milliseconds.

Smart Hybrid vs Standard Hybrid Systems

Standard hybrid systems use fixed capacitor patterns without intelligent switching algorithms and cannot integrate with existing APFC systems. They operate active compensation at maximum levels continuously, resulting in higher costs and shorter equipment life.

SHAF’s smart hybrid approach employs intelligent switching algorithms, seamlessly integrates with existing systems, and optimizes active compensation usage only when required. This approach delivers superior cost-effectiveness while extending existing equipment lifespan.

Implementation and Technical Specifications

System Sizing and Configuration

SHAF systems are optimally sized based on specific load profiles and application requirements. Constant load applications typically require minimal active compensation (10% active, 90% passive), while varying loads benefit from moderate active components (30% active, 70% passive).

Highly dynamic applications with rapidly changing loads achieve optimal performance with higher active compensation ratios (40% active, 60% passive). This flexible sizing approach ensures cost-effective solutions tailored to specific operational requirements.

Installation and Maintenance Benefits

SHAF systems significantly reduce total cost of ownership through decreased maintenance requirements and extended equipment lifespan. The intelligent switching algorithms minimize wear on capacitors and contactors, while precise KVAR delivery eliminates stress from over-compensation cycles.

The user-friendly interface and mobile monitoring capabilities reduce operational complexity and enable proactive maintenance scheduling. Automated fault detection and notification systems minimize downtime and ensure optimal system performance.

Future-Ready Technology for Modern Industries

Compliance with Evolving Regulations

As utility companies increasingly adopt KVAH billing and stricter power quality standards, SHAF technology provides future-proof compliance capabilities. The system’s ability to maintain unity power factor while managing harmonics ensures compliance with current and anticipated regulatory requirements.

Environmental benefits include reduced energy consumption and lower greenhouse gas emissions through improved system efficiency. This aligns with corporate sustainability initiatives and environmental compliance requirements increasingly important for industrial operations.

Scalability and Expansion

SHAF installations demonstrate impressive scalability with over 200,000 Amps of installed capacity across diverse applications. The modular design enables easy system expansion as facility requirements grow, protecting infrastructure investments while accommodating future needs.

The technology’s compatibility with existing systems ensures smooth migration paths from conventional APFC installations without requiring complete system replacement. This approach minimizes installation disruption while maximizing return on existing investments.

SHAF technology represents a transformative advancement in industrial power management, delivering unprecedented combination of cost-effectiveness, performance, and reliability. As industries face increasing pressure to optimize energy consumption and reduce operational costs, SHAF provides a proven solution that addresses both current challenges and future requirements.

The technology’s successful deployment across diverse industries and geographic regions demonstrates its versatility and effectiveness in real-world applications. For industrial facilities seeking to optimize power factor correction, reduce KVAH billing costs, and improve overall system efficiency, SHAF technology offers an compelling path forward.

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

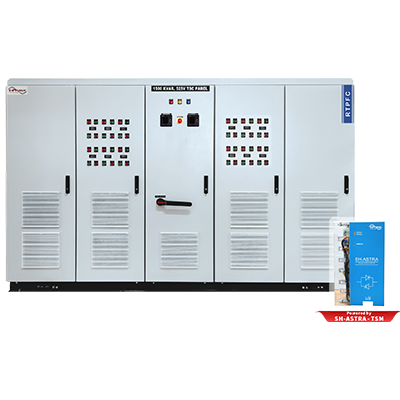

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support