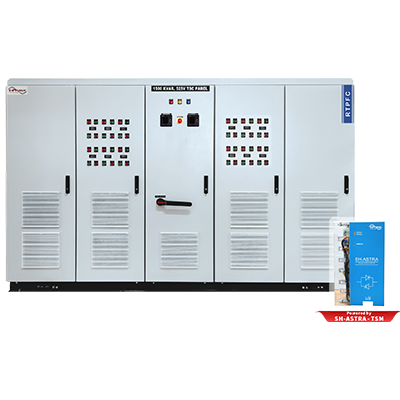

| Rating | 100 Kvar to 1550 Kvar |

| Voltage | 380V to 690V |

| Switching | Contactor Switched |

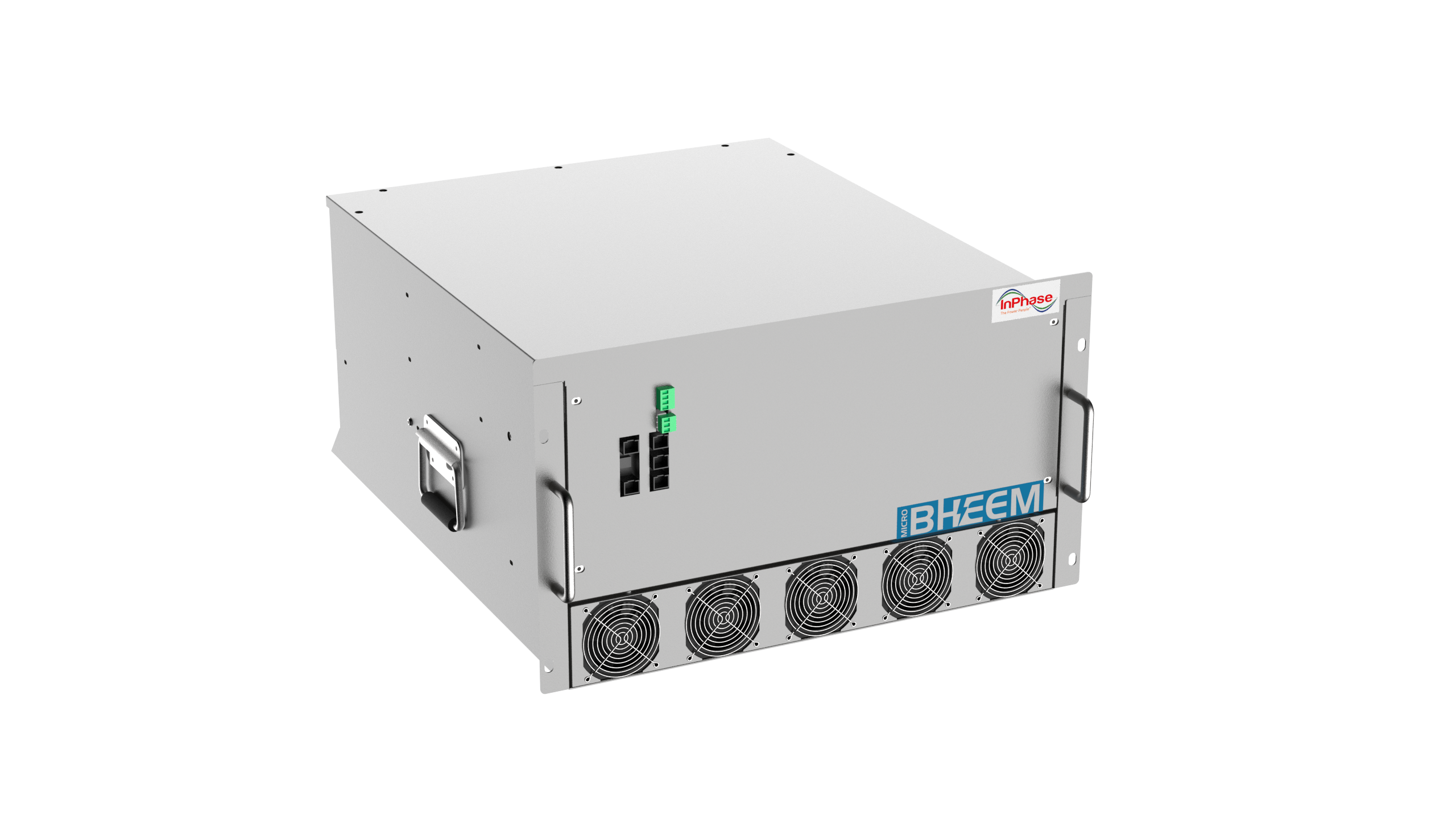

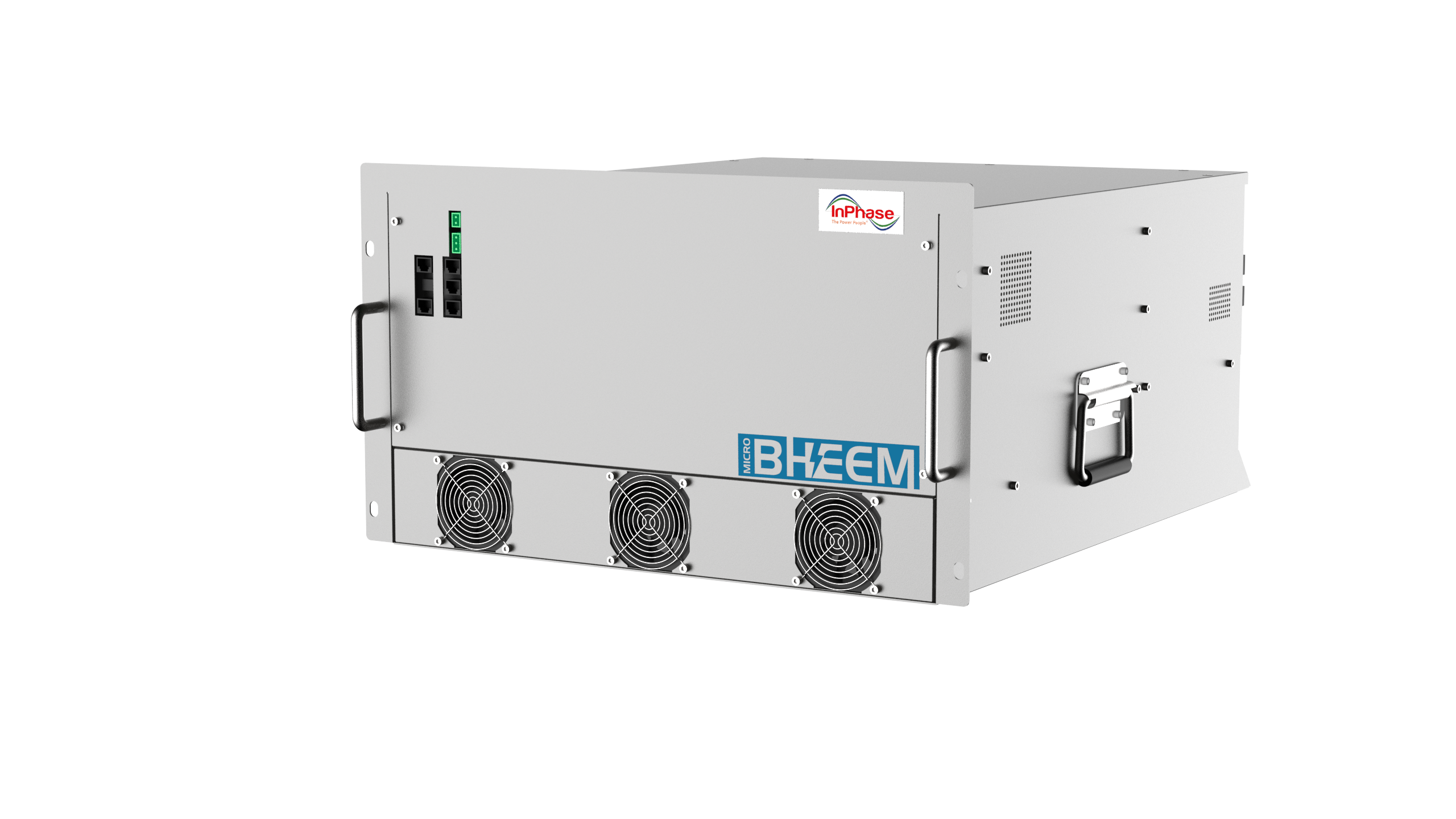

APFC

Power Factor Improvement the Conventional Way

- Advanced microprocessor for Power factor Control

- MPP/APP Gas filled/Oil Filled capacitors

- 440V/525V supported capacitor voltages

- Detuned to avoid resonance

- Extended long life with specially designed reactors

- Complete analysis of customer system before design

- Switchgear used such as contactors, MCCB conform to International and Indian Standards

- Compartmentalized/Non compartmentalized design options

- Power cables suitable for high temperature

- Rugged panel design for long life

For all kinds of Industries to achieve Power Factor Improvement under normal conditions

APFC, an Automatic Power Factor Control, is conventional & old technology consisting of various steps of capacitors that can be switched ON and OFF based upon load demand. APFCs are used only for Reactive power compensation & reduce apparent power demand.

The Power Factor Controller even offers information regarding the network characteristics just like Active, Voltage, reactive power, power factor for the clients to comprehend.

The system commonly incorporates Power Capacitors, Controller, and relay circuits. The switching system of this is dependable upon the kind of compensation. The advanced microprocessor for power factor control can provide complete analysis of the customer system prior to design recommendation is the amazing feature that will undoubtedly impress you. This product’s best feature is its panel designing is extremely simple for user handling & it is a cost-effective solution.

FAQ

An Automatic Power Factor Controller (APFC) panel is an intelligent system designed to automatically maintain the desired power factor in an electrical network. It does this by switching capacitor banks ON or OFF depending on the reactive power demand of the system.

By maintaining unity or near-unity power factor, InPhase APFC panels help industries achieve energy efficiency, reduced losses, and compliance with utility regulations.

Power factor is a measure of how effectively electrical power is converted into useful work output.

A low power factor causes:

- Penalties on electricity bills from utilities

- Higher current flow in cables and transformers

- Voltage drops and overheating of equipment

An InPhase APFC panel ensures optimum power factor, leading to:

✅ Lower energy costs

✅ Extended equipment life

✅ Improved system reliability

InPhase APFC systems are digitally intelligent and IoT-enabled.

Key differentiators:

- <40 ms response time for rapid load compensation

- Advanced controller algorithms for accurate reactive power management

- Thyristor-based switching for seamless, arc-free capacitor operation

- Modular, scalable design adaptable from 50 kVAR to 2000+ kVAR

- Real-time data logging, remote monitoring, and diagnostics

An InPhase APFC panel includes:

- Intelligent APFC Controller with microprocessor logic

- Capacitor banks (standard or detuned type)

- Thyristor or contactor-based switching modules

- Detuned reactors for harmonic protection

- Meters, sensors, relays, and communication modules for monitoring and protection

Each component is carefully selected for industrial-grade performance and long service life.

| Feature | Contactor-based APFC | Thyristor-based APFC |

|---|---|---|

| Switching Type | Mechanical | Electronic (Solid-state) |

| Response Time | 5–10 seconds | <40 milliseconds |

| Application | Stable or slow-varying loads | Rapidly fluctuating loads |

| Maintenance | Periodic contact replacement | Virtually maintenance-free |

| Advantage | Cost-effective | Instant, arc-free, and long life |

InPhase offers both configurations depending on site load characteristics.

Detuned Reactors are inductors connected in series with capacitors to protect them from harmonic distortion and overvoltage.

InPhase uses precisely tuned reactors (typically 189 Hz or 134 Hz) to:

- Prevent resonance with harmonic frequencies

- Extend capacitor lifespan

- Ensure compliance with IEEE 519 harmonic standards

This is critical for plants using VFDs, UPS systems, or nonlinear loads.

✅ Yes.

InPhase APFC panels are designed for complete Power Quality Management. They can be seamlessly integrated with:

- ASTRA (RTPFC) – Real-Time Power Factor Correction for dynamic loads

- SHAF (Active Harmonic Filter) – Active filtering for harmonic mitigation

Together, these systems deliver power factor correction, harmonic reduction, and load balancing — ensuring compliance, energy savings, and stable operations.

The InPhase APFC Controller continuously measures the system’s voltage, current, and power factor.

It calculates the reactive power (kVAR) required to maintain the target power factor and switches capacitor steps ON or OFF accordingly.

Modern InPhase controllers also support:

- Auto-learning of step sizes

- Multiple target PF settings

- Alarm indications for faults or failures

- Data communication (RS485/MODBUS) for remote management

InPhase APFC systems come with:

- Smart LCD or touch-screen displays

- IoT connectivity for remote access

- Data logging & analytics for performance

- tracking

- MODBUS/RS485/TCP-IP protocols for SCADA or BMS integration

Customers can view real-time PF, kVAR, voltage, current, and event logs from anywhere.

InPhase APFC panels are available in a wide range:

- Rating: 50 kVAR to 2500 kVAR or more

- Voltage levels: LT (415V) and HT (3.3kV – 33kV)

- Type: Contactor, Thyristor, or Hybrid-based

- Design: Fixed-step or progressive-step switching

Each panel is custom-engineered based on load profile, harmonic level, and site conditions.

All InPhase APFC systems are built to the highest standards:

- BIS & ISO-certified manufacturing

- Fully type-tested for thermal, electrical, and mechanical endurance

- Overvoltage, overcurrent, and temperature protection

- High-endurance components for continuous industrial operation

- Designed as per IEC 61439-1/2 and IS 8623 standards

InPhase APFC systems are deployed across:

- Steel & Cement Plants

- Automotive & Process Industries

- Commercial Buildings & Data Centers

- Hospitals, Airports & Metro Projects

- Institutions and Utilities

These installations demonstrate proven performance, measurable savings, and sustainability benefits.

Absolutely. InPhase offers cloud-based monitoring and mobile app access, enabling facility teams to:

- Track power factor in real time

- Receive alerts on faults or deviations

- Generate performance reports

- Predict maintenance schedules

This ensures maximum uptime and visibility for electrical infrastructure.

InPhase Power Technologies is a pioneer in indigenous Power Quality Solutions, offering:

- 100% Made-in-India technology

- 15+ years of R&D expertise

- Integrated solutions — ASTRA, SHAF, and APFC

- Proven energy savings & compliance track record

With InPhase, you get innovation, reliability, and service excellence — built for India’s power quality needs.

Temperature has a direct impact on the performance and lifespan of capacitors and thyristor modules.

InPhase APFC panels are engineered for tropical and industrial environments, featuring:

- Derated capacitor banks for high ambient conditions (up to 50°C)

- Temperature-controlled exhaust fans and ventilation design

- Auto-cutoff protection during overheating events

This ensures stable power factor correction even under harsh site conditions.

Every InPhase APFC system is designed and manufactured as per the highest global and Indian standards:

- IEC 60831 – Capacitor standards

- IEC 61439-1/2 – Low-voltage switchgear and controlgear assemblies

- IS 8623 – Indian standard for APFC panels

- IEEE 519 compliance for harmonic mitigation (when combined with SHAF/Detuned Reactors)

- ISO 9001 & ISO 14001-certified manufacturing facility

These ensure consistent quality, reliability, and safety across all installations.

Each industry has distinct load characteristics.

InPhase uses load profiling, harmonic audits, and AI-based simulations to design the most suitable APFC architecture.

Example:

- Cement & Steel plants: Thyristor-based with detuned reactors for VFD loads

- Commercial buildings: Hybrid contactor-thyristor models for mixed loads

- Hospitals/Data centers: Low-noise, EMI-protected, harmonic-safe designs

This customized approach delivers maximum energy efficiency and reliability.

Absolutely. InPhase APFC panels indirectly reduce greenhouse gas emissions by minimizing reactive power losses and improving system efficiency.

Each kVAR correction reduces unnecessary current draw from the grid, leading to:

- Lower kWh consumption

- Reduced transformer and cable losses

- Extended lifespan of electrical assets

This aligns with corporate sustainability and ESG reporting frameworks, supporting a cleaner energy footprint.

Yes, we offer:

- Real-time technical support

- Employee training programs

- Solution design support

- Long-term after-sales service

- Local support: Better accessibility and faster response times

- Proven reliability: 10+ years of industrial experience with ASTRA technology

- Long-term commitment: Guaranteed parts availability and consistent service

- Indian conditions: Designed specifically for harsh Indian industrial environments

- No import risks: No customs delays or currency fluctuation issues

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support