Introduction

Industries with automation and nonlinear loads face harmonics and reactive power imbalance, causing efficiency loss, equipment damage, and utility penalties.

Traditional solutions like capacitor banks and passive filters can’t keep up with dynamic industrial demands. Active filters work but become costly at high power levels.

The Problem: Harmonics + Reactive Power

- Harmonics: VFDs, arc furnaces, UPS, robotics → transformer overheating, nuisance tripping, electronics malfunction, high neutral currents

- Reactive Power Demand: Motors, compressors, furnaces → low PF, penalties, voltage instability, reduced transformer capacity

Conventional Approaches & Limitations

- Passive filters: low-cost but inflexible

- Active filters: costly for large loads

- Capacitor banks/APFC: slow and ineffective for harmonics

The Solution: Hybrid Harmonic Filters (HHF)

- Passive section: handles bulk reactive compensation & lower-order harmonics

- Active section: monitors in real-time, cancels higher-order harmonics, balances loads

Why HHF Stands Out

- Scalable power quality management

- Cost-effective for large loads

- Dynamic compensation within milliseconds

- Ensures IEEE-519 compliance and near-unity PF

- Built for harsh industrial environments

Applications

- Steel Plants: stabilize extreme harmonics and reactive swings

- Cement Industry: handle heavy reactive loads

- Textile Industry: VFD-heavy operations

- Renewable Integration: manage inverter harmonics

- Large Manufacturing Facilities: improve efficiency and compliance

Case Example (Hypothetical)

Cement plant in Gujarat installed 2000 kVAR HHF:

- PF improved to 0.99

- THD reduced <4%

- Transformer overheating incidents down 15%

- ₹18 lakhs annual savings

Why Choose InPhase HHF?

- Tailored solutions for customer load profiles

- Proven 24/7 reliability

- Modular scalability

- Backed by InPhase expertise

FAQs

- Difference from AHF? HHF combines passive+active, cost-effective for large industries

- Power factor improvement? Yes, near-unity PF

- Avoid penalties? Ensures IEEE-519 compliance

- Renewable suitability? Yes, for solar/wind with inverters

- Equipment life impact? Reduces harmonics and voltage stress, extending transformer/motor lifespan

Conclusion

HHFs combine passive and active strengths to deliver scalable, cost-effective solutions. InPhase HHFs provide grid compliance, efficiency, lower costs, and extended equipment life—making them essential for modern industrial competitiveness.

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

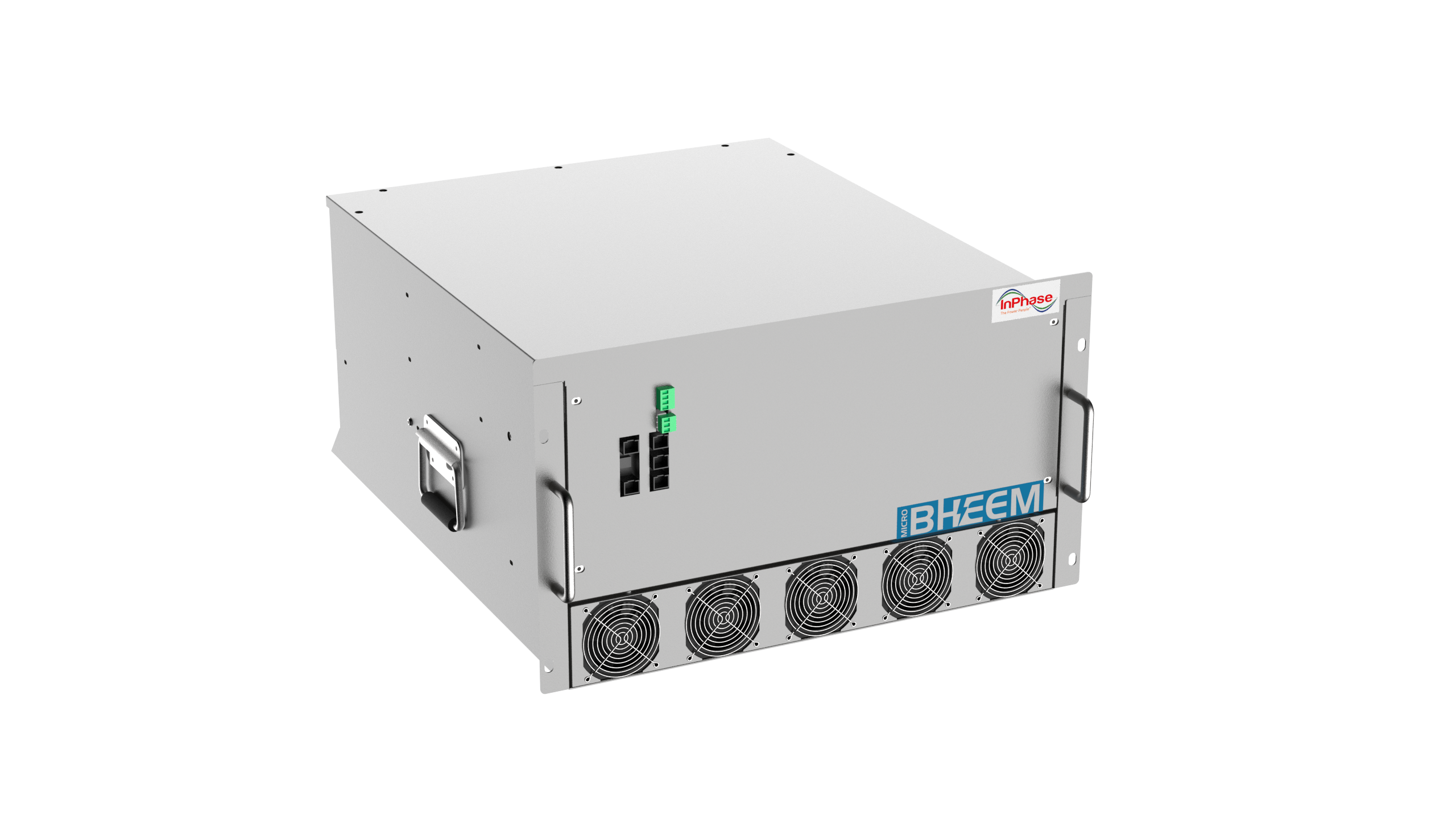

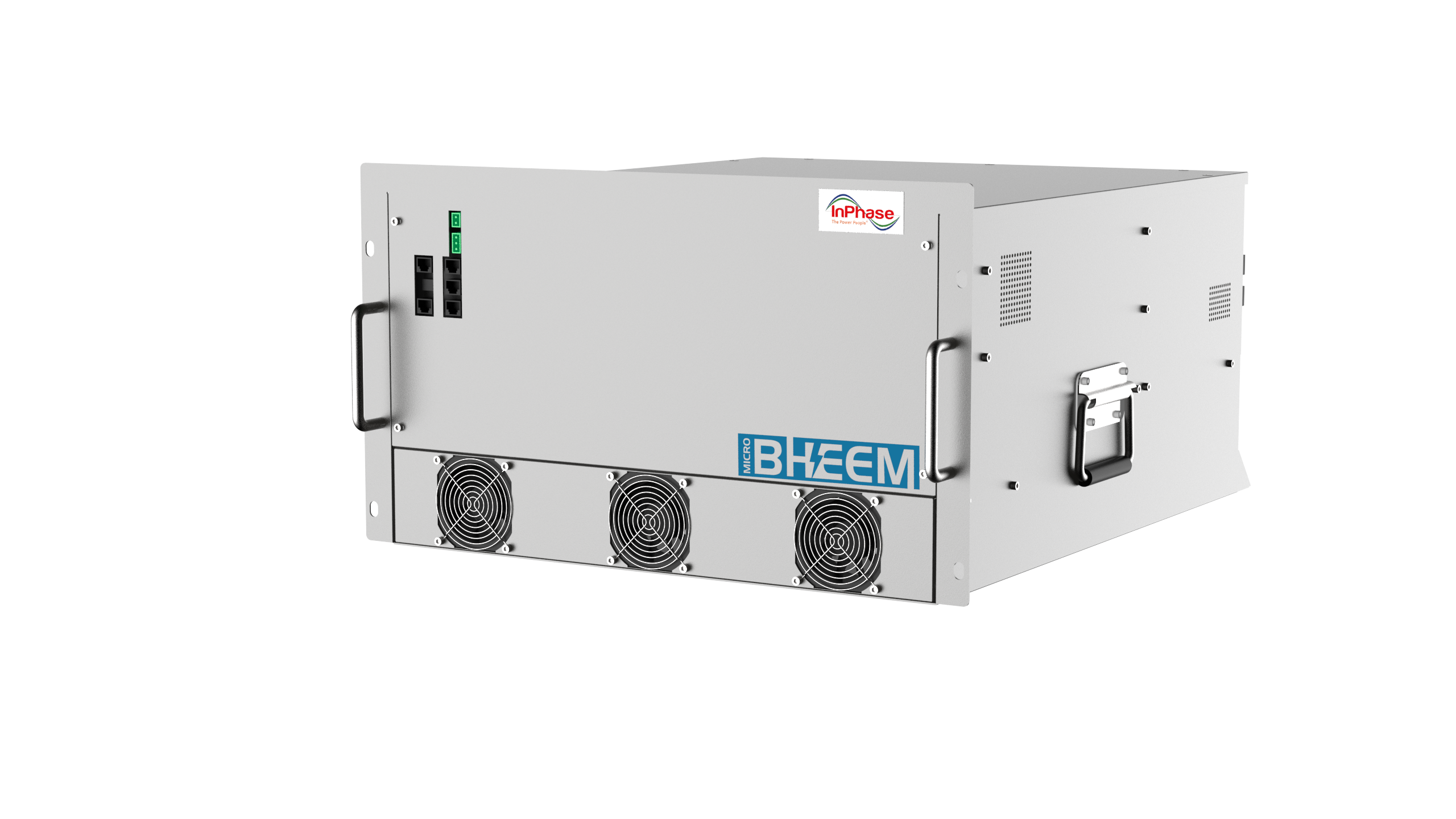

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

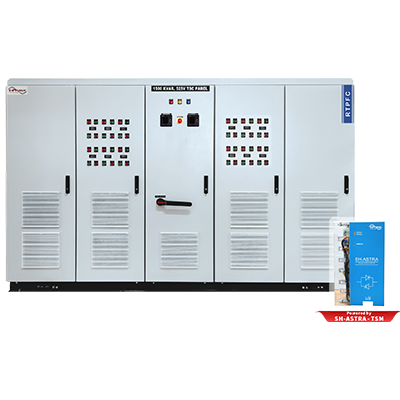

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support