Active Harmonic Filters: Complete Guide to THD Reduction & Power Quality Solutions 2025

Industrial electrical systems face increasing power quality challenges from nonlinear devices that generate harmonic distortion, causing equipment failures, energy losses, and regulatory compliance issues. Active Harmonic Filters (AHF) provide the most effective solution for comprehensive harmonic mitigation and power quality improvement across diverse industries.

Understanding Harmonic Distortion in Modern Electrical Systems

Sources of Harmonic Generation

Nonlinear electrical devices create harmonic currents even when applied voltage is perfectly sinusoidal. These devices have proliferated across industrial and commercial facilities, significantly increasing harmonic pollution in electrical distribution systems.

Common Harmonic-Generating Equipment:

-

LED and CFL lighting systems

-

Switch Mode Power Supply (SMPS) units in computers and PLCs

-

Variable frequency drives controlling motors and pumps

-

Uninterruptible Power Supply (UPS) systems

-

Arc furnaces and SCR temperature controllers

-

Battery chargers and rectifier systems

Power Factor Relationship and Calculations

The fundamental relationship between apparent power, real power, and reactive power is expressed by the power triangle formula :

kVA2=kW2+kVAR2

Power Factor is calculated as:

PF=kWkVA

In harmonic-rich environments, true power factor becomes:

True PF=Displacement PF×Distortion PF

IEEE 519 and CEA Standards Compliance

Regulatory Requirements and Harmonic Limits

Power quality regulations mandate strict harmonic limits based on system characteristics. The IEEE 519-2022 standard establishes current distortion limits using the short-circuit ratio:

Ratio=ISCIL

Where:

-

ISC = Maximum short-circuit current at PCC

-

IL = Maximum demand load current at PCC

Total Demand Distortion (TDD) Calculation

TDD differs from THD by using maximum demand current as the reference:

TDD=∑h=2∞Ih2IL×100%

While THD uses fundamental current:

THD=∑h=2∞Ih2I1×100%

IEEE 519 Current Distortion Limits (120V-69kV Systems):

| ISC/IL | 3≤h<11 | 11≤h<17 | 17≤h<23 | 23≤h<35 | 35≤h≤50 | TDD |

|---|---|---|---|---|---|---|

| <20 | 4.0% | 2.0% | 1.5% | 0.6% | 0.3% | 5.0% |

| 20<50 | 7.0% | 3.5% | 2.5% | 1.0% | 0.5% | 8.0% |

| 50<100 | 10.0% | 4.5% | 4.0% | 1.5% | 0.7% | 12.0% |

| 100<1000 | 12.0% | 5.5% | 5.0% | 2.0% | 1.0% | 15.0% |

| >1000 | 15.0% | 7.0% | 6.0% | 2.5% | 1.4% | 20.0% |

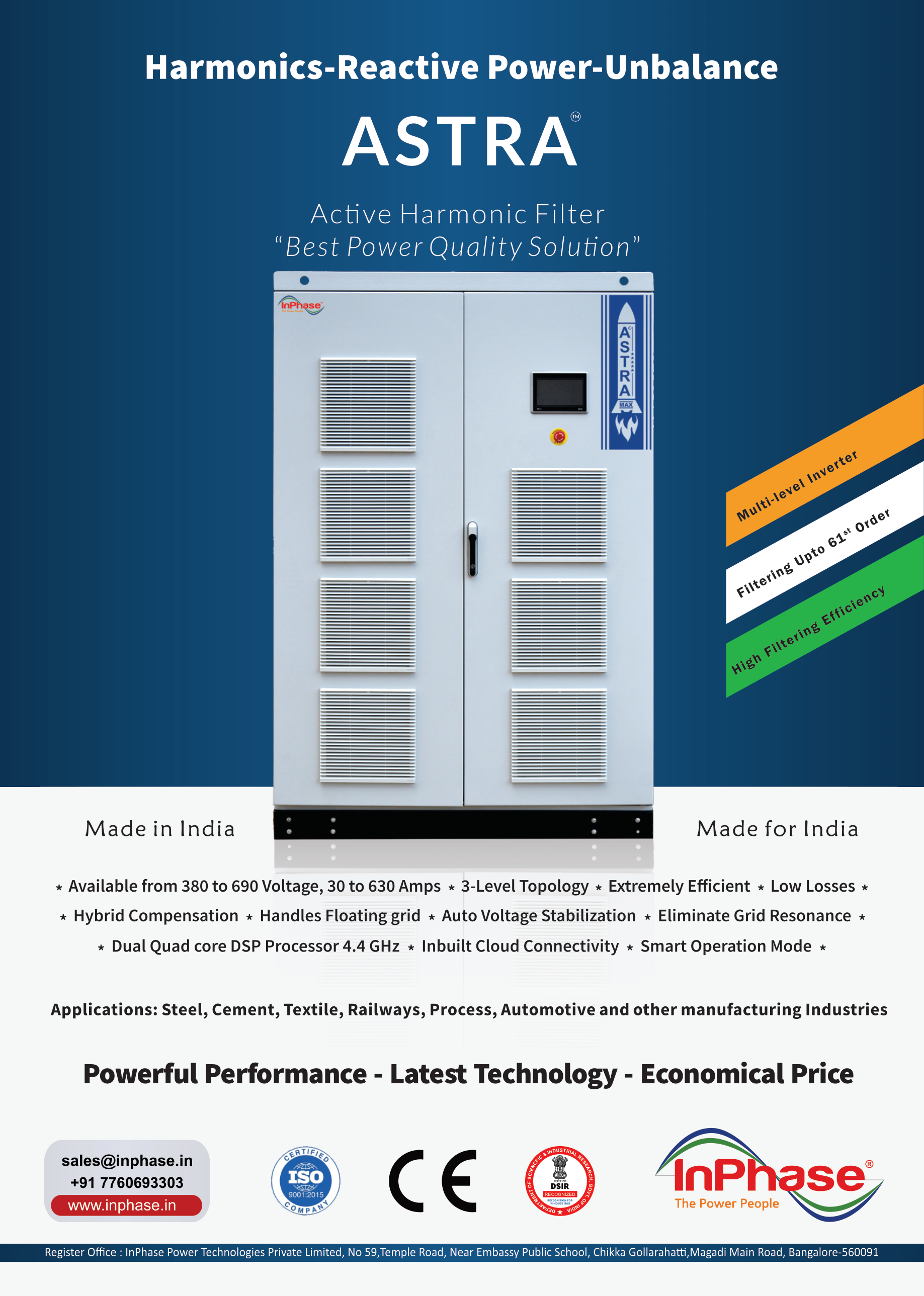

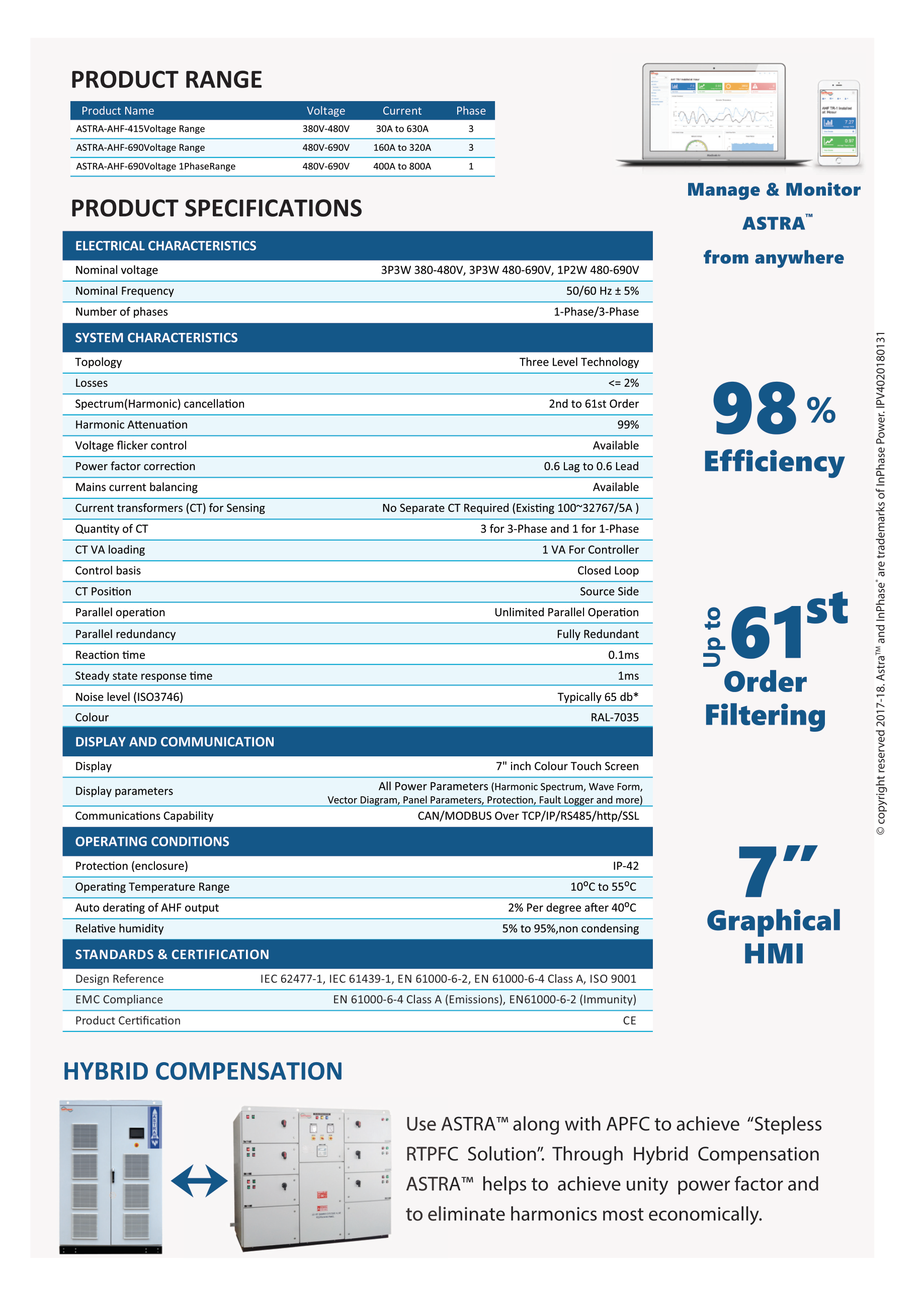

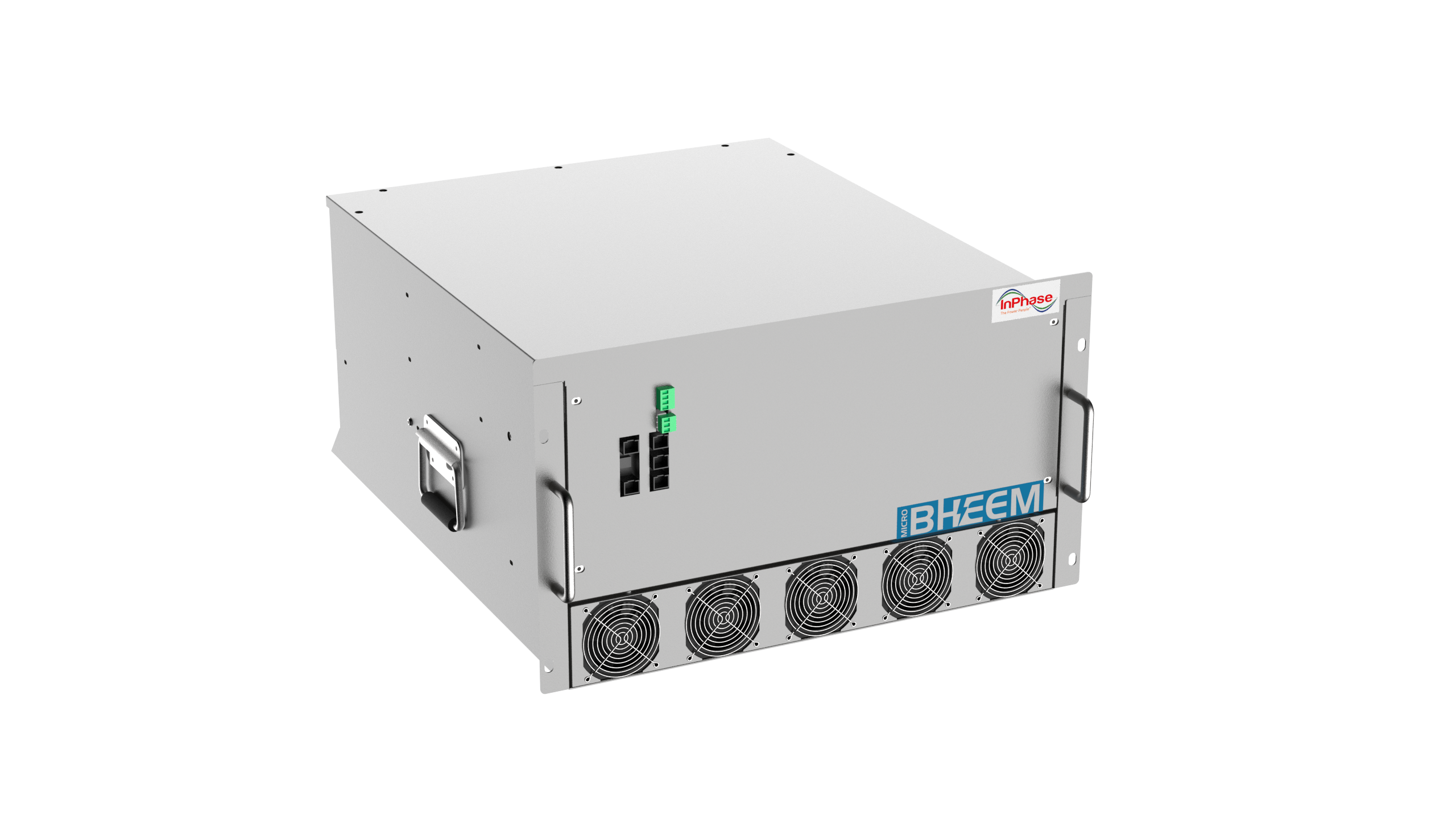

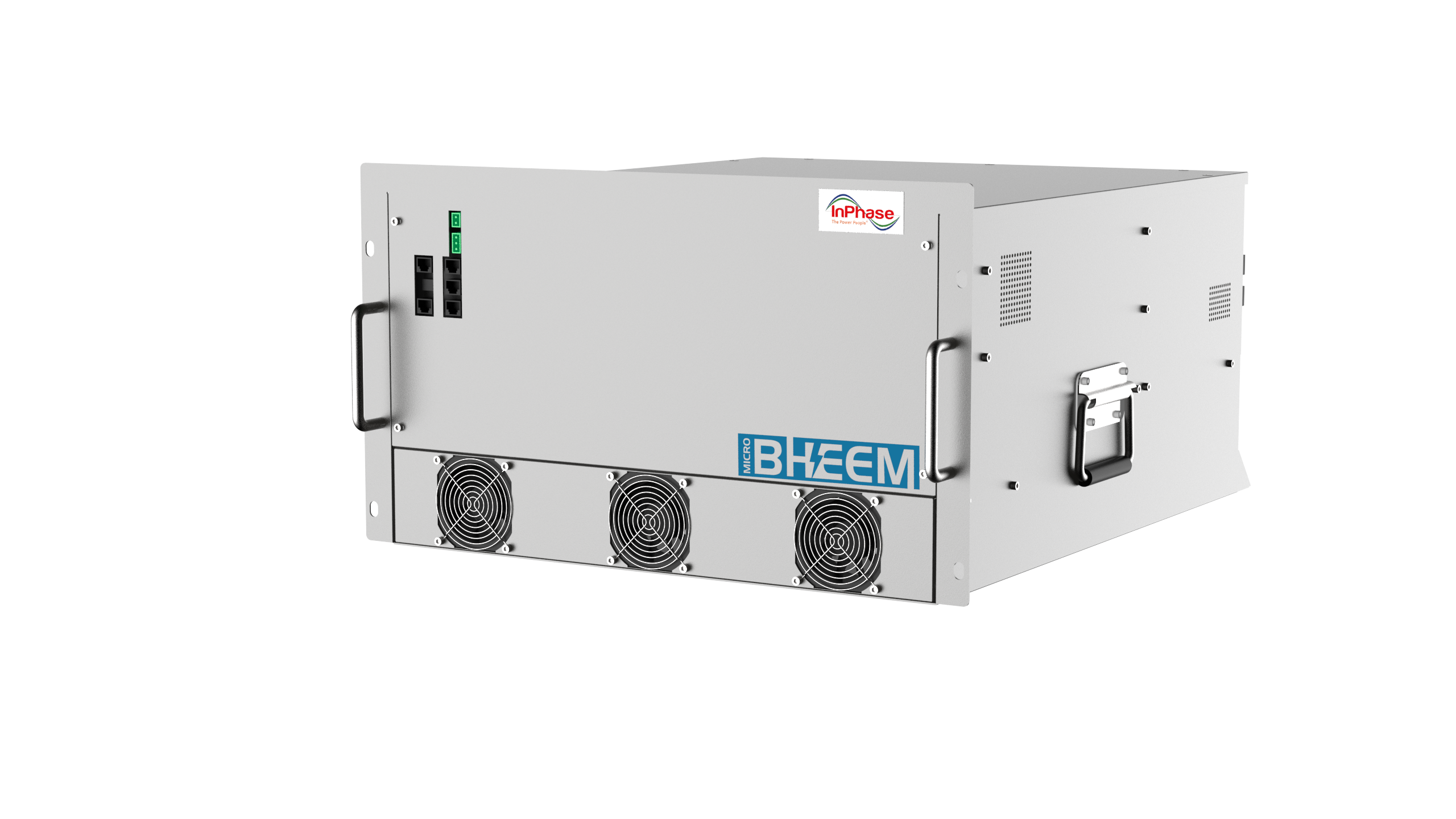

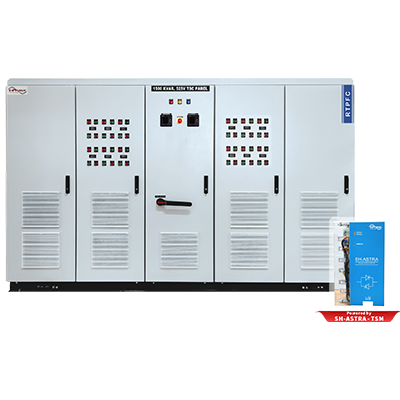

InPhase Astra Active Harmonic Filter Technology

Advanced Multi-Level Inverter Design

The InPhase Astra AHF represents cutting-edge harmonic filtering technology featuring :

Superior 3-Level Topology:

-

Filtering capability up to 61st order harmonics

-

Multi-level inverter technology for superior waveform quality

-

High filtering efficiency minimizing system losses

-

Reduced electromagnetic interference and switching stress

Advanced Processing Power:

-

Dual quad-core DSP processor operating at 4.4 GHz

-

Real-time harmonic analysis and compensation

-

Intelligent control algorithms for optimal performance

-

Cloud connectivity for remote monitoring and diagnostics

Active Harmonic Filter Working Principle

Parallel Connection Strategy

Active Harmonic Filters connect in parallel (shunt) configuration with three-phase electrical systems:

-

Real-Time Current Monitoring: Current transformers measure load currents continuously

-

Harmonic Detection: Advanced algorithms identify specific harmonic frequencies and magnitudes

-

Compensation Current Generation: System injects currents 180° out of phase with detected harmonics

-

Dynamic Cancellation: Harmonic currents are effectively cancelled, reducing THDi to acceptable levels

The compensation current equation:

Icompensation=−Iharmonic

Industry Case Studies with Measured Results

Food Processing Industry Application

Initial Conditions:

-

THDi: 18% (predominantly 5th harmonic)

-

Power Factor: 0.85 lagging

-

Frequent electronic component failures

Solution: 200A Active Harmonic Filter at PCC

Results After Installation:

-

THDi reduced to <8% (compliant with DISCOM regulations)

-

Power Factor improved to >0.95

-

Zero electronic component failures reported

IT/ITES Sector Implementation

Pre-Installation Measurements:

-

THDi: 24% (predominantly 5th harmonic at 18%)

-

7th harmonic: 12%

-

11th harmonic: 8%

-

Power Factor: 0.78

Solution: 75A Active Harmonic Filter

Post-Installation Results:

-

THDi reduced to <5%

-

5th harmonic: <3%

-

Power Factor: >0.95

-

Energy savings: 12% reduction in losses

Textile Manufacturing Success

Baseline Measurements:

-

THDi: 12% (5th harmonic dominant at 9%)

-

Frequent capacitor bank failures (monthly)

-

Transformer temperature: 85°C average

Solution: 600A Active Harmonic Filter system

Achieved Performance:

-

THDi reduced to <3%

-

Zero capacitor bank failures over 12 months

-

Transformer temperature: 70°C average

-

Annual energy savings: ₹2.5 million

Technical Specifications and Performance

InPhase Astra AHF Features

Performance Characteristics:

-

Voltage Range: 380V to 690V systems

-

Current Ratings: 30A to 630A capacity

-

Filtering Range: Up to 61st order harmonics

-

Response Time: <20 milliseconds

-

Efficiency: >98% at rated load

-

THD Reduction: Typically, 85-95% improvement

Advanced Technology Benefits:

-

CE Certification for European standards compliance

-

Made in India for local conditions optimization

-

Hybrid compensation capabilities

-

Auto voltage stabilization

-

Grid resonance elimination

Installation and Application Guidelines

System Design Calculations

For proper AHF sizing, calculate the harmonic current requirement:

IAHF=∑h=2∞Ih,load2

The minimum AHF rating should be:

RatingAHF=IAHF×Vsystem×3×Safety Factor

Where Safety Factor typically ranges from 1.15 to 1.25 for future load growth.

Performance Verification

Post-installation verification requires measurement of:

-

Individual harmonic currents (Ih)

-

Total Harmonic Distortion (THDI)

-

Total Demand Distortion (TDD)

-

Power Factor improvement

-

Energy efficiency gains

Return on Investment Analysis

Quantified Benefits

Direct Cost Savings:

-

Utility penalty elimination: ₹500,000 – ₹2,000,000 annually

-

Energy efficiency gains: 3-8% reduction in losses

-

Equipment life extension: 25-40% increase

-

Maintenance cost reduction: 30-50% decrease

Payback Period Calculation:

Payback=Initial InvestmentAnnual Savings+Energy Savings+Penalty Avoidance

Typical payback periods range from 12-24 months depending on application severity and utility penalty structures.

Conclusion

Active Harmonic Filters represent the most effective solution for comprehensive power quality improvement in modern industrial facilities. The InPhase Astra AHF, with its advanced 3-level topology and intelligent processing capabilities, delivers superior performance for:

-

Complete harmonic mitigation up to 61st order frequencies

-

IEEE 519 compliance with TDD reduction from 15-20% to <5%

-

True power factor improvement addressing both displacement and distortion components

-

Equipment protection extending operational lifespan by 25-40%

-

Energy efficiency optimization reducing system losses by 3-8%

The mathematical relationships and measured case study results demonstrate that properly engineered Active Harmonic Filter solutions provide immediate power quality improvements while delivering substantial long-term operational and financial benefits.

Power Factor Improvement

Power Factor Improvement KVAH Billing Reduction

KVAH Billing Reduction Captive Power PF Improvement

Captive Power PF Improvement Harmonics Mitigation

Harmonics Mitigation Drives Harmonic Mitigation

Drives Harmonic Mitigation Unbalance Compensation

Unbalance Compensation Active Harmonic Filter

Active Harmonic Filter Static VAR Generator

Static VAR Generator Modular AHF

Modular AHF Modular SVG

Modular SVG Smart Hybrid Active Filter

Smart Hybrid Active Filter APFC

APFC RTPFC

RTPFC Power Quality Study

Power Quality Study Energy Audit

Energy Audit Harmonics Analysis

Harmonics Analysis Product Support

Product Support