- Harmonic currents were high, the THDi was between 17-20% which is higher than the IEEE 519-2014 norms.

- High Voltage Notches were also present in the plant.

- Presence of even order harmonics which is normally zero in other plants.

- Hot rolling mill loads were highly fluctuating and load patterns were abnormal.

- The voltage varied up to 470V which is an abnormal behaviour.

Here, the main challenge faced while giving solution was to suppress current harmonics or THDi to less than 8% in an environment with high voltage spikes and indefinitely fluctuating plant load condition.

SOLUTION PROVIDED BY INPHASE : InPhase proposed 2 x 450 Amps, 415V Active Harmonic Filter (Model:IPC150-AHF-450-V415) with CAN-bus communication that acts as a single 900A system. Specially designed RC tank circuits were incorporated to handle notches and rigorous algorithm for high fluctuating loads. This was the most cost effective, as well as the technically correct method to handle the situation. The 2 number of AHFs were connected in BUS A & BUS B, as the load distributes in those buses. The whole system has been pictorially described in the diagram below.

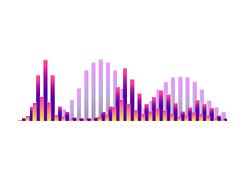

The graph indicates the harmonic currents of various orders (3rd to 13th) before and after installation of Active Harmonic Filter. The successful installation of 2 x 450A Active Harmonic Filter has reduced the THDi from 17% to 4-5%, well below than the limits mentioned in IEEE 514-2014. This solution has helped the customer not only to cut down penalties but also to reduce failure of sensitive equipments which are vulnerable to harmonics. Also, various production losses were averted. Overall, InPhase was able to solve a problem of harmonics in very poor power quality environment. This was another feather in InPhase‘s cap. We would be extremely happy to help customers who face such outrageous Power Quality problems because at InPhase we are happy to tackle power quality challenges for our customers.

Get in touch today.

Meet you again with a interesting article, until then bye from Dr.InPhase

Thank you!

Thanks for reading…if you have questions don’t forget to ask me. You could write to me to info@inphase.in or call +91 9632421402

InPhase Power is a Power Electronic Product company manufacturing products for Power Quality and Power Conversion. InPhase is manufacturer of Active Filter, Active Harmonic Filter, Solar Inverter. InPhase majors in power system design for power quality and conversion. Driven by a management that has a combined experience of over 60 years in power system and power electronics InPhase nurtures innovation and passion in this field.